Premium Custom Auto Wire Harness Solutions | Kaweei High-Quality Cable Assemblies

Kaweei: Your Trusted Manufacturer for Premium Custom Auto Wire Harness Solutions

High-quality wire harnesses are essential for efficient power distribution, signal transmission, and system integration in automotive electrical systems. At Kaweei, we specialize in custom automotive wire harness solutions, ensuring superior performance, durability, and reliability. Our manufacturing expertise, advanced technology, and stringent quality control make us a preferred wire harness manufacturer for global automotive brands.

1. What is an Automotive Wire Harness?

A wire harness, also known as a cable assembly, is a structured arrangement of wires, connectors, terminals, and protective sheaths that transmit electrical signals or power within a vehicle. Unlike loose wires, a professionally engineered automotive wire harness enhances electrical performance, reduces the risk of short circuits, and ensures seamless integration with various vehicle components.

2. Why Choose Kaweei for Custom Wire Harness Solutions?

At Kaweei, we go beyond just manufacturing wire harnesses—we engineer high-quality, customized solutions tailored to the requirements of automotive manufacturers, OEMs, and aftermarket suppliers. Our key advantages include:

A. High-Quality Materials

We use premium UL-certified wires, tin-plated copper conductors, durable PVC insulation, and flame-retardant sheaths to ensure optimal conductivity and long-term reliability.

B. Advanced Manufacturing & Precision Engineering

Our state-of-the-art production facility is equipped with:

- Automated wire cutting, stripping, and crimping machines for precision processing

- Laser welding technology to ensure strong and stable electrical connections

- Injection molding for robust and waterproof harnesses

- Quality testing laboratories to perform continuity checks, insulation resistance testing, and high-voltage stress tests

C. Customization & OEM Solutions

Kaweei offers custom wire harness design and development, ensuring compatibility with:

- Automotive lighting systems

- Engine management systems

- Infotainment and navigation systems

- EV battery and charging cables

- Safety and sensor wiring

D. Industry Compliance & Certification

We adhere to ISO 9001, IATF 16949, and RoHS compliance to meet global automotive industry standards.

3. Kaweei’s Wire Harness Manufacturing Process

Step 1: Wire Selection & Cutting

We use high-quality copper conductors with various insulation options based on voltage, heat resistance, and flexibility requirements. Automated cutting and stripping machines ensure precise wire lengths.

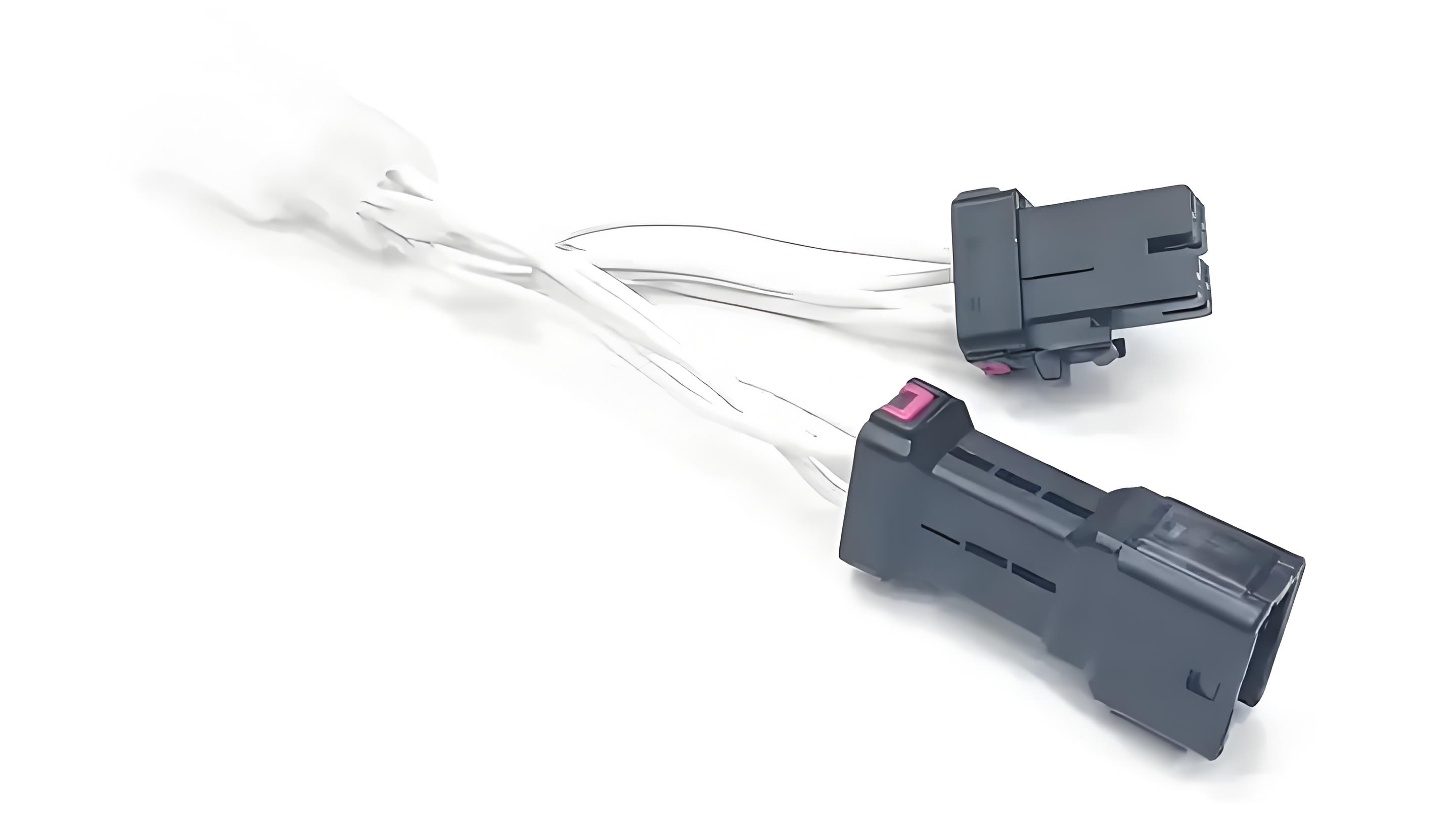

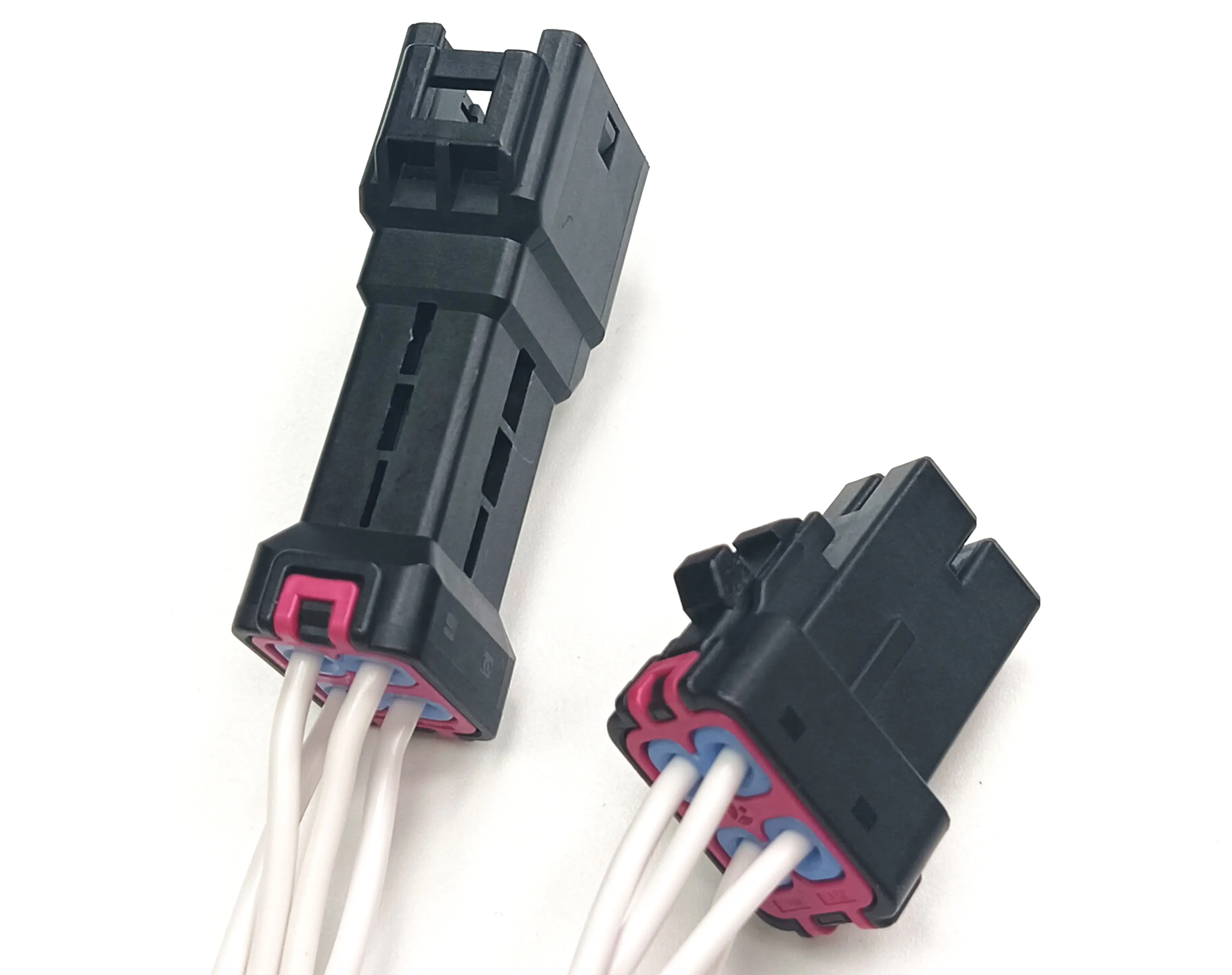

Step 2: Terminal Crimping & Connector Assembly

Each wire undergoes automated crimping to ensure secure and reliable connections. We use TE, Molex, and JST connectors, ensuring industry-standard compatibility.

Step 3: Cable Routing & Bundling

Our expert technicians follow design schematics to carefully route and bundle wires, optimizing space utilization and electrical efficiency.

Step 4: Insulation & Protective Sheathing

We apply heat shrink tubing, braided sleeving, and PVC jackets to protect against abrasion, heat, and moisture.

Step 5: Quality Control & Testing

Each harness undergoes rigorous testing, including:

- Continuity and insulation resistance tests

- Voltage drop and current load assessments

- Environmental and durability stress tests

4. Applications of Kaweei’s Automotive Wire Harnesses

Our custom auto wire harness solutions cater to a wide range of applications, including:

- Electric Vehicles (EVs) & Hybrid Cars – High-voltage battery wiring, charging connectors, and power distribution systems

- Passenger Cars & Trucks – Infotainment, lighting, and safety system wiring

- Heavy Machinery & Industrial Vehicles – Engine wiring, hydraulic control cables, and transmission harnesses

- Motorcycles & ATVs – Compact, high-performance harness solutions for power sports applications

5. Why High-Quality Wire Harnesses Matter in Automotive Applications

A reliable wire harness enhances vehicle performance by:

✅ Reducing electrical faults and short circuits

✅ Improving fuel efficiency with optimized wiring layouts

✅ Enhancing safety through durable insulation and shielding

✅ Minimizing maintenance costs with long-lasting, corrosion-resistant materials

6. Partner with Kaweei for Premium Wire Harness Solutions

At Kaweei, we are committed to delivering high-performance, custom automotive wire harnesses tailored to your exact needs. With our cutting-edge manufacturing technology, premium materials, and rigorous quality control, we ensure superior electrical solutions that meet the highest industry standards.

Looking for a trusted automotive wire harness supplier? Contact Kaweei today and let us provide the perfect custom cable assembly solutions for your applications.