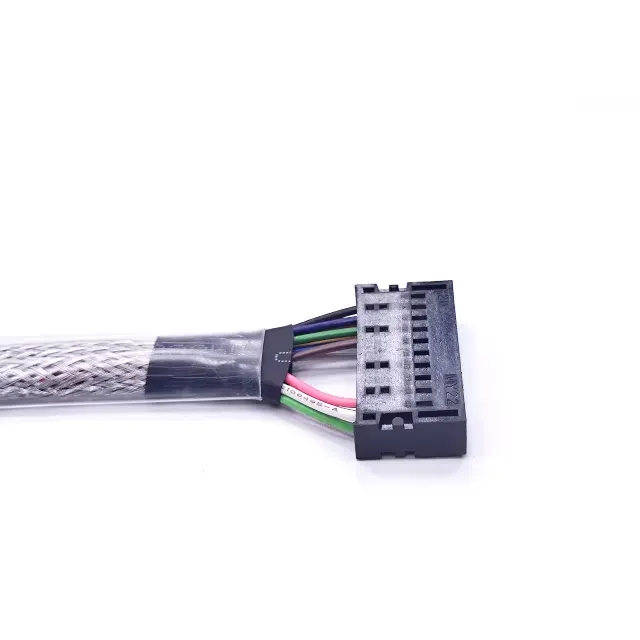

Custom Shielded Dental Equipment Wire Harness | 20-Pin Medical Cable Assembly

Precision-engineered for dental medical devices, this custom 20-pin wire harness features a 2.54mm pitch interface and UL1007 26AWG conductors. Enhanced with a ferrite core and shielding braid for superior EMI suppression, it ensures interference-free operation for sensitive dental scanners and diagnostic tools. Built with robust insulation materials, it offers the durability and safety required for clinical environments.

Reliable Interconnect Solutions for Medical Technology

Kaweei specializes in the assembly of high-performance wire harnesses for the medical industry. For sensitive dental equipment like intraoral scanners and curing lights, signal integrity is non-negotiable. We provide custom-manufactured cable assemblies that integrate EMI suppression components and durable insulation to ensure patient safety and device accuracy in clinical settings.

| Design Element | Technical Specification | Kaweei Assembly Expertise |

|---|---|---|

| EMI Protection | Ferrite Core + Braided Shield | Noise Suppression: We integrate ferrite cores and terminate shielding braids precisely to block electromagnetic interference, ensuring clear images and data transmission for diagnostic tools. |

| Interconnection | 2.54mm Pitch / 20-Pin | Precision Termination: Handling high-pin-count (20P) connectors requires strict process control. We ensure every crimp is gas-tight and every pin is seated correctly to prevent intermittent failures. |

| Wire Selection | UL1007 26AWG | Medical Grade Sourcing: We source high-quality UL-certified wires with insulation options (PVC/PTFE/Nylon) that resist chemical cleaning agents commonly used in dental clinics. |

| Durability | Insulation Materials | Wear Resistance: Dental cables are frequently moved and bent. We apply durable jacketing or sleeving to protect the internal conductors from mechanical stress and fatigue. |

| Quality Assurance | 100% Testing | Zero Error: Every medical harness undergoes continuity, miswiring, and isolation testing to ensure it meets the rigorous safety standards required for medical devices. |

Why Shielding Matters in Dental Equipment

In a dental office full of electronic devices, interference can cause equipment malfunction. Kaweei ensures signal purity:

- Ferrite Core Integration: We install ferrite beads at calculated positions on the harness to filter out high-frequency noise spikes.

- Grounding Logic: A shield is useless if not grounded. We ensure the drain wire or braid is properly connected to the connector shell or ground pin for effective EMI drainage.

- Clean Assembly: Our manufacturing environment controls contaminants, ensuring the harness is clean and ready for integration into medical housings.

Technical Specifications

| Temperature Rating | 80 |

| Voltage Rating | 450 |

Key Features

Oil & Corrosion Resistance

Premium PUR/TPE jacket provides excellent resistance to industrial cutting oils, coolants, acids, and alkalis.

Easy Installation

Standardized interface dimensions support quick assembly and disassembly, reducing on-site maintenance costs.

Eco-Friendly

All materials comply with RoHS 2.0 and REACH directives; halogen-free and non-polluting to the environment.

Multi-Certified

Products hold CE, UL, TUV, and other authoritative certifications, ensuring reliability for global markets.