What is Cable Assembly?

Efficient systems in the aerospace, telecommunications, and automotive industries rely heavily on well-designed cable assemblies to ensure seamless operation. A high-quality cable assembly system guarantees reliable power, signal, and data transmission, which is essential for the performance of sophisticated equipment and machinery. For professionals involved in hardware development, manufacturing, or supplier management, a thorough understanding of the fundamentals of cable assemblies—including their structure, manufacturing processes, and key procedures—can help optimize system performance while balancing cost and quality.

This guide provides a systematic introduction to the core aspects of cable assemblies, covering types, required materials and tools, interpretation of wiring diagrams, preparation steps, crimping and soldering techniques, insulation and bundling methods, continuity testing, and safety precautions. It aims to serve as a professional and practical reference for industry practitioners.

Overview of Cable Assemblies

A cable assembly is an integrated module consisting of wires, connectors, terminals, and other components systematically arranged to meet specific electrical or communication requirements. Its primary function is to ensure stable transmission of power, signals, or data within complex equipment. Customized cable assemblies are widely used in industries such as automotive, aerospace, telecommunications, and medical technology, where off-the-shelf solutions often fail to meet design specifications, making tailored solutions critical for system compatibility and reliability.

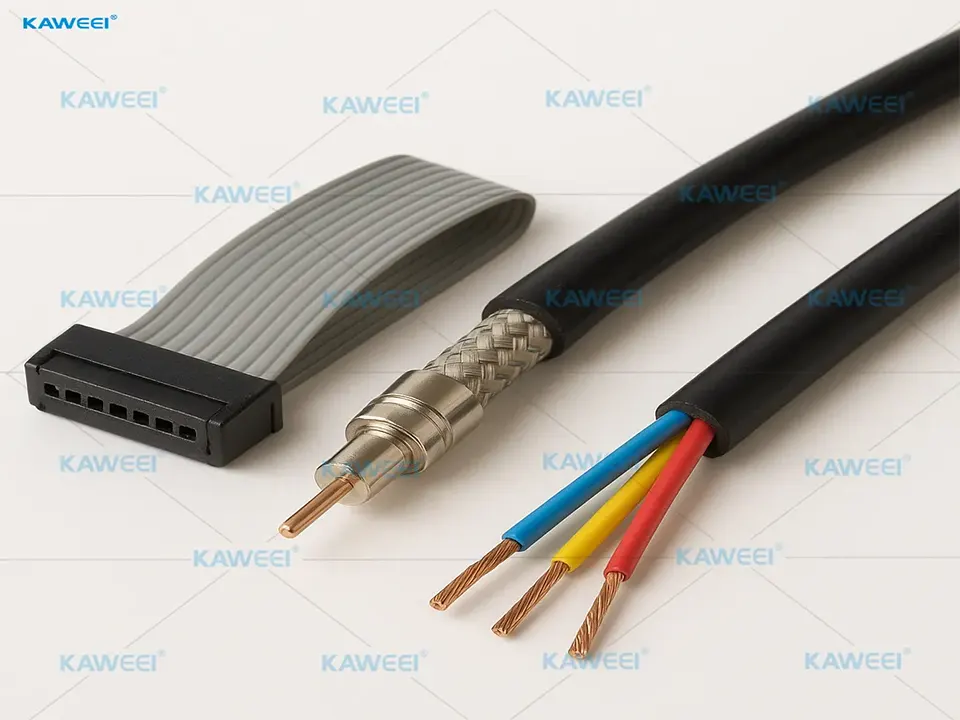

Types of Cable Assemblies

Depending on application requirements, cable assemblies can be categorized into several types. Flat ribbon cables are suitable for compact devices such as computers and printers where space is limited. Coaxial cable assemblies, known for their resistance to electromagnetic interference, are commonly used in communication and broadcasting systems. Multi-conductor cables allow transmission of multiple signals within a single cable and are ideal for complex industrial equipment. Selecting the appropriate type is essential for achieving the optimal balance of performance, space efficiency, and reliability.

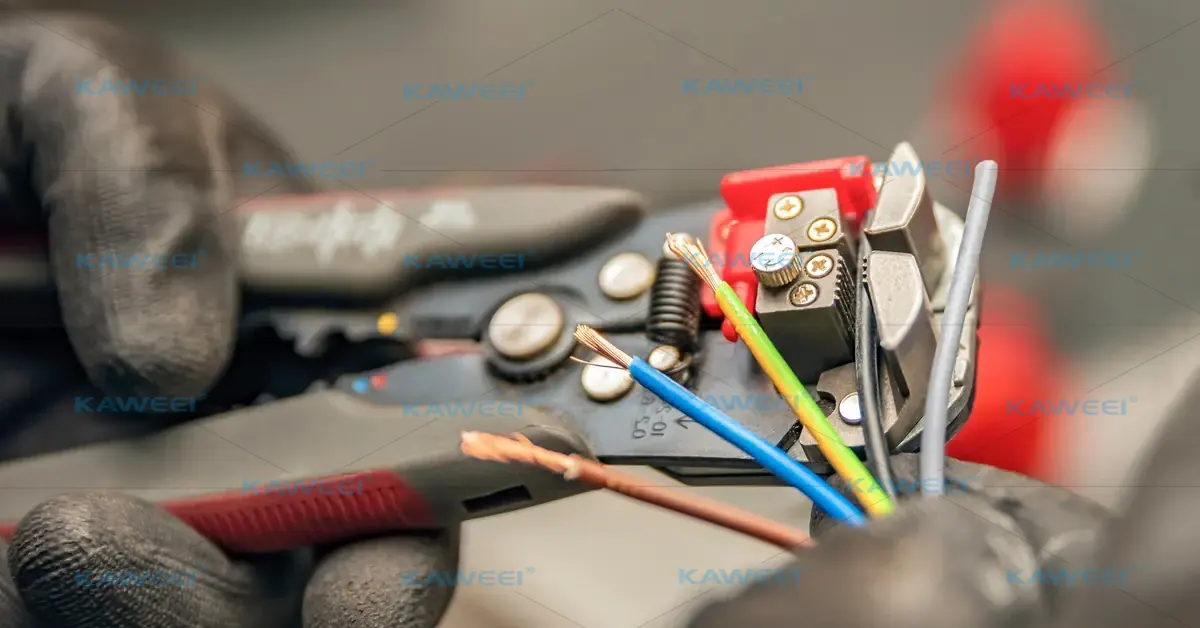

Tools and Materials

Professional, high-precision tools are fundamental to producing high-quality cable assemblies. These include wire cutters, strippers, crimping tools, and soldering irons. Materials must comply with industry standards and include wires, insulation, heat-shrink tubing, and connectors to ensure durability and functional consistency. Partnering with experienced suppliers, such as CTEMS Company, can help ensure material quality and technical expertise for mission-critical applications.

Understanding Wiring Diagrams

Wiring diagrams serve as the blueprint for cable assemblies, using standardized symbols to illustrate the connections between wires, connectors, and terminals. Accurately interpreting these diagrams enables engineers to identify connection points, plan routing paths, and ensure compliance with technical specifications. Well-documented wiring diagrams significantly reduce errors and enhance manufacturing efficiency, serving as a key tool for quality control.

Preparation Before Assembly

An efficient and error-free cable assembly process begins with a clean and organized workspace. All tools and materials should be categorized and easily accessible, with adequate lighting and cleanliness. Wires must be precisely measured and cut according to design requirements, and all components should be clearly labeled. These preparatory steps help minimize errors and improve overall production efficiency.

Crimping Process

Crimping is a process that deforms a metal sleeve to securely join terminals or connectors to wires. It directly affects the mechanical strength and electrical conductivity of the connection. Operators should use correctly sized terminals, maintain consistent pressure, and perform visual and pull tests on finished crimps to avoid connection failures or system malfunctions.

Soldering Techniques

Soldering is used to create permanent electrical connections, especially in environments with vibration or thermal cycling. High-quality soldering requires proper heating techniques, suitable solder materials, and flux application. Surfaces must be thoroughly cleaned before soldering to ensure low resistance and long-term reliability.

Insulation and Bundling

Insulation, such as heat-shrink tubing and insulating tape, protects cable connections from mechanical damage and environmental exposure. Bundling keeps cables organized and facilitates installation and maintenance. Common bundling tools include cable ties and Velcro straps, which help manage wiring in a flexible and structured manner.

Continuity Testing

Continuity testing with a multimeter is an essential quality control step after assembly. This test identifies open circuits, miswiring, or poor connections, ensuring that the assembled cable functions correctly. Detecting defects early helps prevent system failures and reduces post-deployment costs.

Safety Precautions

Cable assembly involves working with live wires, sharp tools, and high-temperature equipment, requiring strict adherence to safety protocols. Operators should wear protective gear such as safety glasses and insulated gloves, ensure electrical isolation in the work area, and follow tool operating instructions to prevent accidents.

Common Mistakes and Solutions

Common issues in cable assembly include incorrect wire gauge selection, poorly executed crimps, and skipping continuity tests. These oversights can lead to degraded electrical performance, connection failures, or system interruptions. Strict adherence to design specifications, use of reliable tools, and implementing inspection points at critical stages can significantly improve product consistency and service life.

Applications and Advantages

From automotive wiring harnesses and avionics to telecommunications infrastructure, cable assemblies play a vital role in integrating connections and enhancing system reliability. Custom assembly services can optimize configurations based on project requirements, significantly improving installation efficiency, reducing downtime, and enhancing overall operational performance.