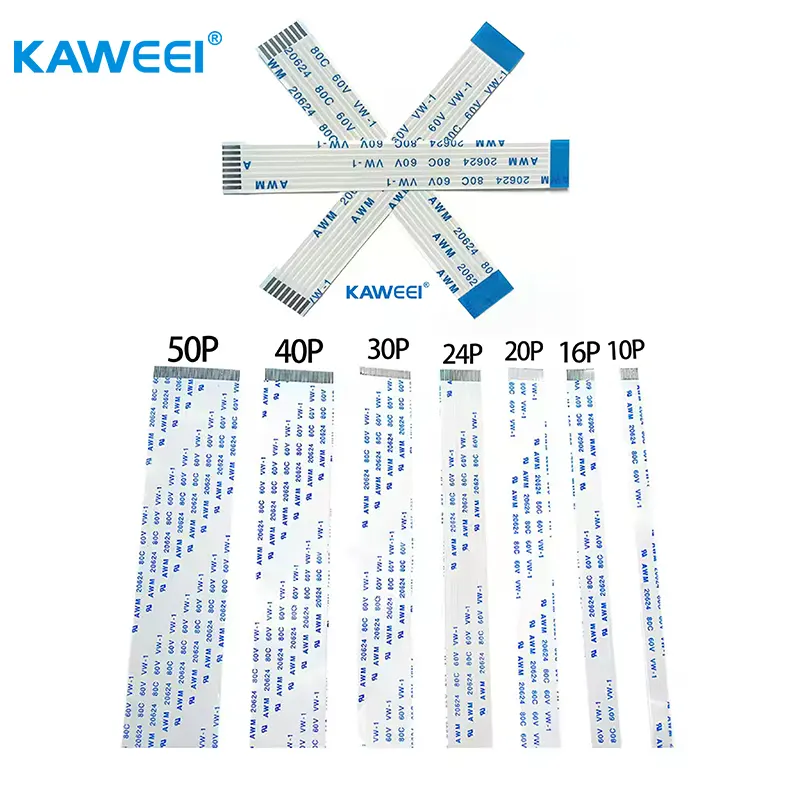

Custom FFC Cable Assembly (2-50 Pin)

Reliable Automotive FFC Cable Assembly designed for harsh environments. Available in Custom lengths with 2-50 pin pitch options. Premium Flexible Flat Cable and wire harness manufacturing for vehicle electronics.

Custom FFC Interconnect Solutions for High-Density Electronics

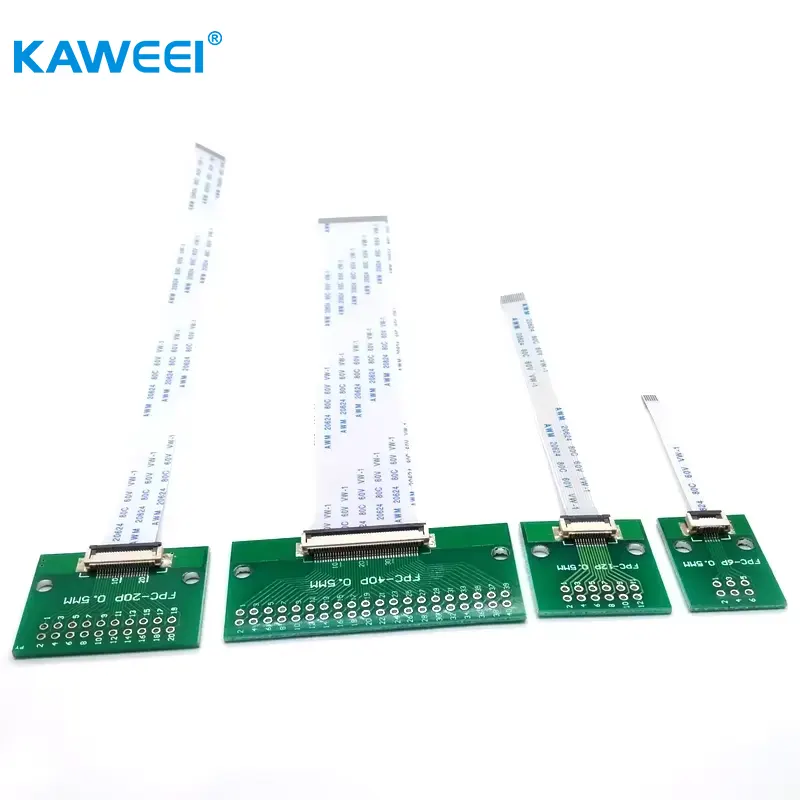

Kaweei provides specialized flexible flat cable (FFC) processing and assembly solutions. While we utilize high-grade industry-standard raw FFC materials, our value lies in customizing these flat cables to fit the precise mechanical and electrical constraints of your device, ranging from 2 to 50 pins.

| Configuration Param | Standard Options | Kaweei Customization Service |

|---|---|---|

| Pin Count & Pitch | 2 - 50 Pins (0.5mm / 1.0mm / 1.25mm) | We cut and process FFCs to your exact circuit requirements, ensuring precise mating with ZIF/LIF connectors on your PCB. |

| Contact Orientation | Type A (Same Side) / Type B (Opposite Side) | We configure the contact exposure (gold or tin plated) to match your board-to-board layout, preventing installation polarity errors. |

| Mechanical Shaping | Straight / Flat | Folding Service: We provide precision creasing and folding (accordion, 90-degree, etc.) so the cable fits into tight housings without stress. |

| EMI Shielding | Unshielded | Value-Add: We can wrap FFCs in conductive cloth, aluminum foil, or apply grounded shielding films to prevent signal interference in sensitive displays. |

| Stiffener Reinforcement | Standard Blue/White Tape | We apply custom-length support tapes (stiffeners) to the connection ends to ensure a secure grip within the connector mechanism. |

Why Choose Kaweei for FFC Processing?

Connecting two PCBs in a compact space requires more than just a standard cable. We turn standard FFCs into installation-ready components:

- Precision Cutting: Custom lengths down to the millimeter to avoid excess slack inside your product.

- Protection Application: We can apply acetate cloth tape or protective sheathing over the cable body to prevent abrasion against internal chassis components.

- Hybrid Assembly: If your design requires it, we can integrate ferrite cores for noise suppression or combine FFCs with traditional wiring looms.

Technical Specifications

| Wire Type | PVC/PET |

| Wire Gauge (AWG) | 20706 |

| Voltage Rating | 60V |

| Temperature Rating | 105℃ |

Key Features

Wide Temperature Range

Designed for -40°C to +105°C, ensuring stable operation from freezing outdoors to high-temperature workshops.

High Flexibility

Special drag chain cable material resistant to repeated bending and torsion, with a service life exceeding 5 million cycles.

Easy Installation

Standardized interface dimensions support quick assembly and disassembly, reducing on-site maintenance costs.

Multi-Certified

Products hold CE, UL, TUV, and other authoritative certifications, ensuring reliability for global markets.