Custom Shielded Cables for EMI Protection

As electronic devices become smaller and more integrated, electromagnetic interference (EMI) has become a major factor affecting signal stability. Shielded cables are widely used in automotive electronics, industrial control systems, communication networks, and medical equipment. By adding one or more conductive layers—such as aluminum foil, tinned copper braid, or composite shielding—between the conductor and outer jacket, these cables effectively block external interference and prevent signal leakage, maintaining accurate and stable data transmission.

For applications with specific requirements, custom shielded cables offer better performance than standard products. Each application environment demands different cable characteristics: automotive systems often require oil and heat resistance, communication equipment focuses on high-frequency EMI suppression, and medical devices prioritize low noise and high stability. Manufacturers design and adjust the shielding method, conductor structure, and insulation materials based on the environment, signal type, and installation needs.

The choice of shielding material and structure has a direct impact on EMI protection. Aluminum foil shielding works best for high-frequency interference, while tinned copper braid provides stronger low-frequency isolation for power and control systems. In more complex environments, a composite shielding structure can be used to balance both high and low-frequency protection.

Conductors and insulation materials also play a key role in cable performance. High-purity copper or tinned copper improves conductivity and corrosion resistance, while insulation materials such as XLPE, FEP, or silicone enhance heat tolerance and mechanical durability. The outer jacket can be customized with waterproof, oil-resistant, flame-retardant, or flexible features to ensure long-term reliability in harsh environments.

The customization process typically includes requirement confirmation, sample design, testing, and mass production after validation. Common quality tests include EMI shielding effectiveness, grounding resistance, bending endurance, and insulation voltage tests. These procedures ensure every cable meets international standards and performs reliably under real-world operating conditions.

In summary, the selection and customization of shielded cables should be driven by actual application needs. Using the right shielding design, materials, and verified testing is essential to reducing EMI risks, maintaining signal integrity, and ensuring long-term system reliability. For systems requiring stable transmission and strong EMI protection, custom shielded cables are a practical and effective solution.

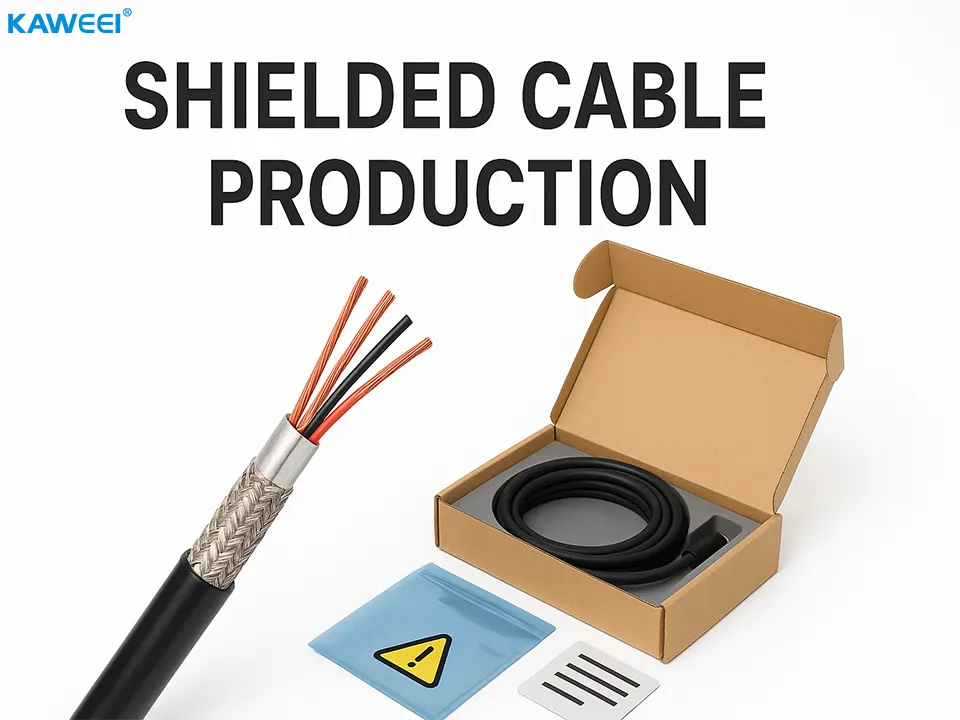

For custom wire harnesses or shielded cables, Kaweei is a trusted manufacturer. We provide reliable, EMI-resistant solutions for all your needs. Contact us anytime for custom orders.

Frequently Asked Questions About Shielded Cable Production

1. What is a shielded cable and why is it important?

A shielded cable is a type of wire harness that includes a conductive layer to block external electromagnetic interference (EMI) and radio frequency interference (RFI). It helps maintain signal integrity and system stability in complex electronic environments.

2. What are the key steps in Kaweei’s shielded cable production process?

Kaweei’s production process follows strict standards for precision stripping, reliable grounding, insulation protection, and final packaging. Each step is monitored through quality checkpoints to ensure consistent electrical performance and long-term durability.

3. How does Kaweei ensure EMI performance and reliability?

Kaweei uses advanced testing equipment to verify shielding effectiveness and grounding resistance. Every cable is subjected to EMI and continuity testing before shipment, ensuring it meets or exceeds international performance requirements for industrial, automotive, and communication applications.

4. What packaging standards does Kaweei follow for wire harness shipments?

Kaweei adopts customized protective packaging, including anti-static materials, foam inserts, and batch-labeled trays. Each shipment is designed to minimize vibration, moisture exposure, and handling damage during transportation, guaranteeing product quality upon delivery.

5. Why choose Kaweei as your shielded wire harness supplier?

Kaweei is a professional wire harness manufacturer with extensive experience in high-performance shielded cable solutions. By combining automated production, precise craftsmanship, and standardized packaging, Kaweei delivers reliable, EMI-resistant cable assemblies trusted by global OEMs and industrial clients.