How to Use Butt Connectors?

Butt Connectors are electrical connectors specifically designed to join two wire ends securely and reliably, providing a stable electrical connection without the need for soldering. They play a critical role in custom wiring harness assemblies, ensuring that multiple conductors are mechanically and electrically connected with high reliability.

Structure and Working Principle

A standard Butt Connector consists of a metal sleeve—usually copper or tin-plated copper—with openings on both ends, covered by an insulating layer or heat-shrink tubing. When two stripped wire ends are inserted into each side of the connector and compressed with a crimping tool, a solid mechanical and electrical connection is formed. Some models feature heat-shrink and waterproof designs. When heated, the tubing contracts while the internal adhesive melts, sealing the joint and providing additional protection against water ingress, corrosion, and environmental stress.

Applications and Advantages

Butt Connectors are widely used in automotive wire harnesses, marine wiring, and industrial electrical systems. Compared to traditional soldering, crimped Butt Connectors offer faster installation, easier handling, and greater suitability for confined or hard-to-access locations. The built-in insulation prevents short circuits and electrical shocks, while heat-shrink variants offer added resistance against moisture, oil, and vibration, significantly enhancing the durability and reliability of the wiring harness.

Installation Considerations

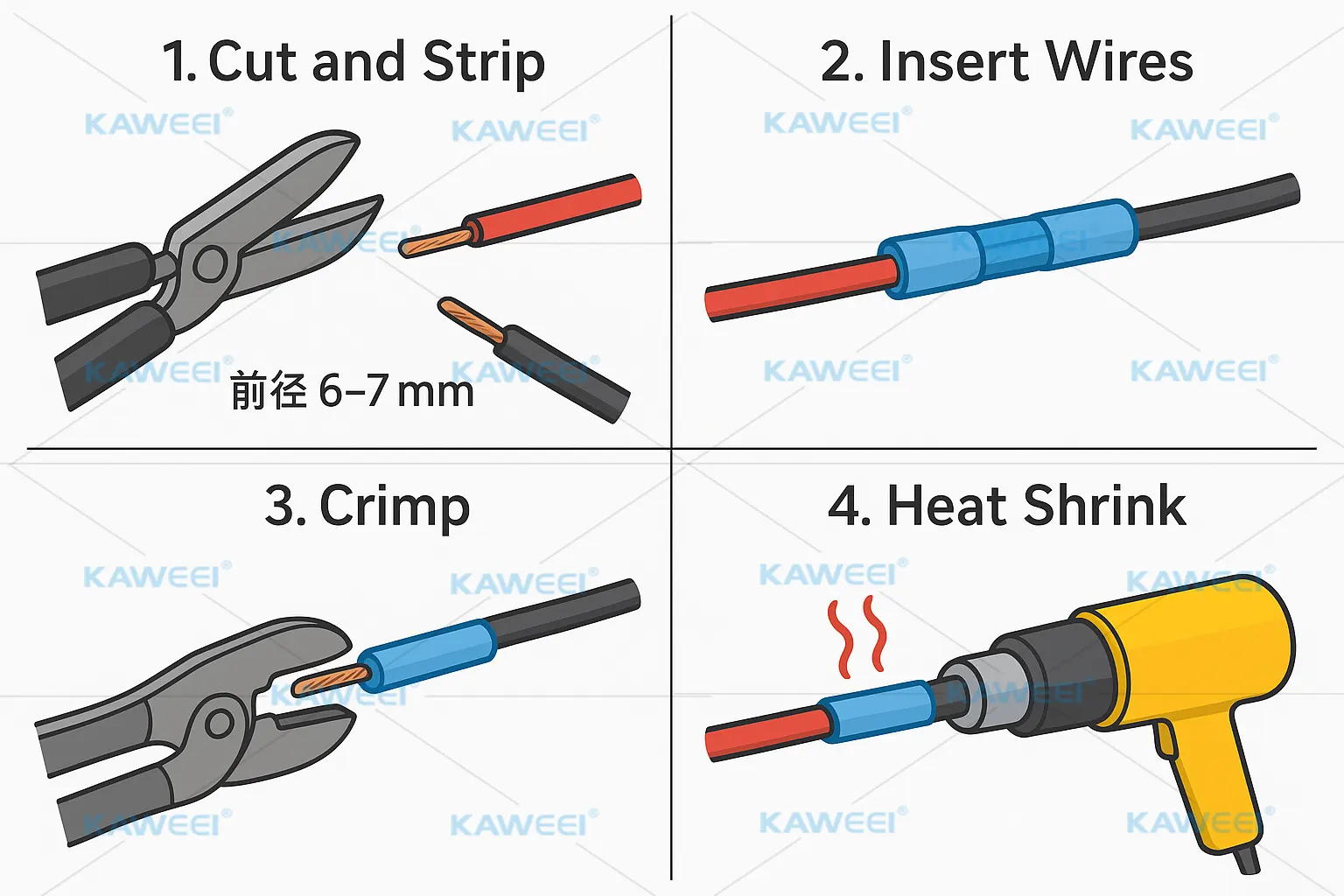

In practical use, wires should be cut cleanly and stripped approximately 6–7 mm, ensuring that the copper strands remain intact. Insert the wire ends fully into the metal sleeve of the Butt Connector, then use a properly sized crimping tool to secure the connection. For heat-shrink Butt Connectors, apply heat using a heat gun or flame to shrink the tubing and activate the adhesive, creating a sealed, waterproof, and vibration-resistant joint. Non-heat-shrink connectors should be insulated with electrical tape. It is essential to select Butt Connectors that match the wire gauge and to maintain clean, dry wires during crimping, avoiding overheating to ensure long-term reliability.

Overall, Butt Connectors provide a professional, efficient, and reliable solution for wire-to-wire connections in custom harness manufacturing. They facilitate quick installation, simplify maintenance, and allow for easy wire replacement without compromising the integrity of the original wiring structure, making them indispensable in high-quality wiring harness design and assembly.

Kaweei is a professional custom wire harness manufacturer, specializing in designing and producing high-quality wiring solutions for automotive, marine, and industrial applications. We offer tailored wire harnesses to meet your specific project needs, ensuring reliable and durable electrical connections. For inquiries or custom orders, you can contact us anytime — our team is always ready to provide expert support and solutions.

1. What is Kaweei and what does it specialize in?

Kaweei is a professional wire harness manufacturer specializing in custom wiring solutions for automotive, marine, and industrial applications. They provide high-quality, reliable wire harnesses tailored to specific project requirements.

2. What are custom wire harnesses?

Custom wire harnesses are pre-assembled sets of wires, connectors, and terminals designed to meet unique electrical and mechanical specifications. They simplify installation, improve reliability, and ensure long-lasting performance in complex electrical systems.

3. How do Butt Connectors play a role in Kaweei’s custom wire harnesses?

Butt Connectors are used in Kaweei’s wire harnesses to join two wires securely without soldering. They ensure stable electrical connections, improve durability, and can feature heat-shrink designs for waterproof and vibration-resistant protection.

4. Why choose Kaweei for custom wiring harnesses?

Kaweei offers expert design, high-quality components, and precise assembly, ensuring each custom wire harness meets the client’s specifications. Their solutions are efficient, reliable, and suitable for harsh environments where long-term performance is critical.

5. How can I order a custom wire harness from Kaweei?

Clients can contact Kaweei with their wiring diagrams, specifications, or project requirements. Kaweei will design, manufacture, and deliver a fully customized wire harness solution, optimized for performance, durability, and ease of installation.