The Difference between PCB and PCBA

In electronics manufacturing, PCB and PCBA are often mentioned in the same breath — sometimes even as if they mean the same thing. But anyone who’s ever worked on a production floor or debugged a live board knows they’re not interchangeable. They mark two distinct phases in how an idea becomes a working electronic product.

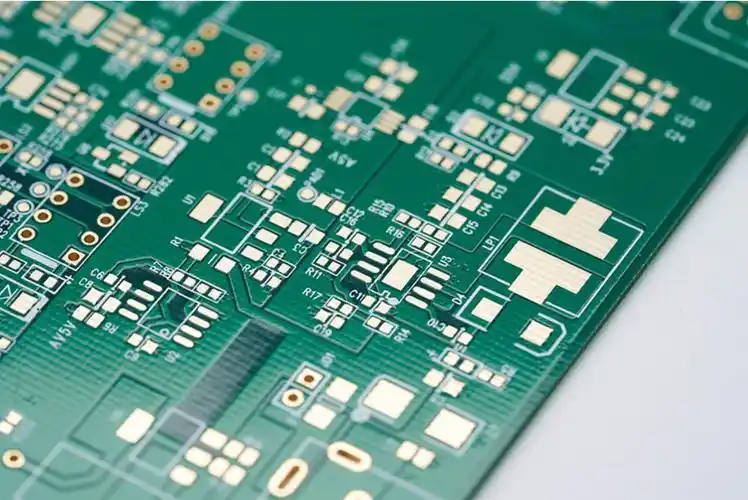

What Exactly Is a PCB?

A Printed Circuit Board (PCB) is where every electronic product begins. Think of it as the physical backbone that everything else depends on. It’s made of insulating substrate and copper layers, where the traces are etched or printed to create pathways for electrical signals.

A well-designed PCB isn’t just about routing signals — it’s about managing impedance, controlling interference, and ensuring reliability under real-world stress. In today’s compact devices, PCB design has become almost an art of balance: fitting more functionality into less space without sacrificing signal integrity.

Automation and standardization have made PCB fabrication remarkably consistent, but design quality still defines performance. Even small layout changes — a misplaced via, an overly long trace — can ripple through the entire system.

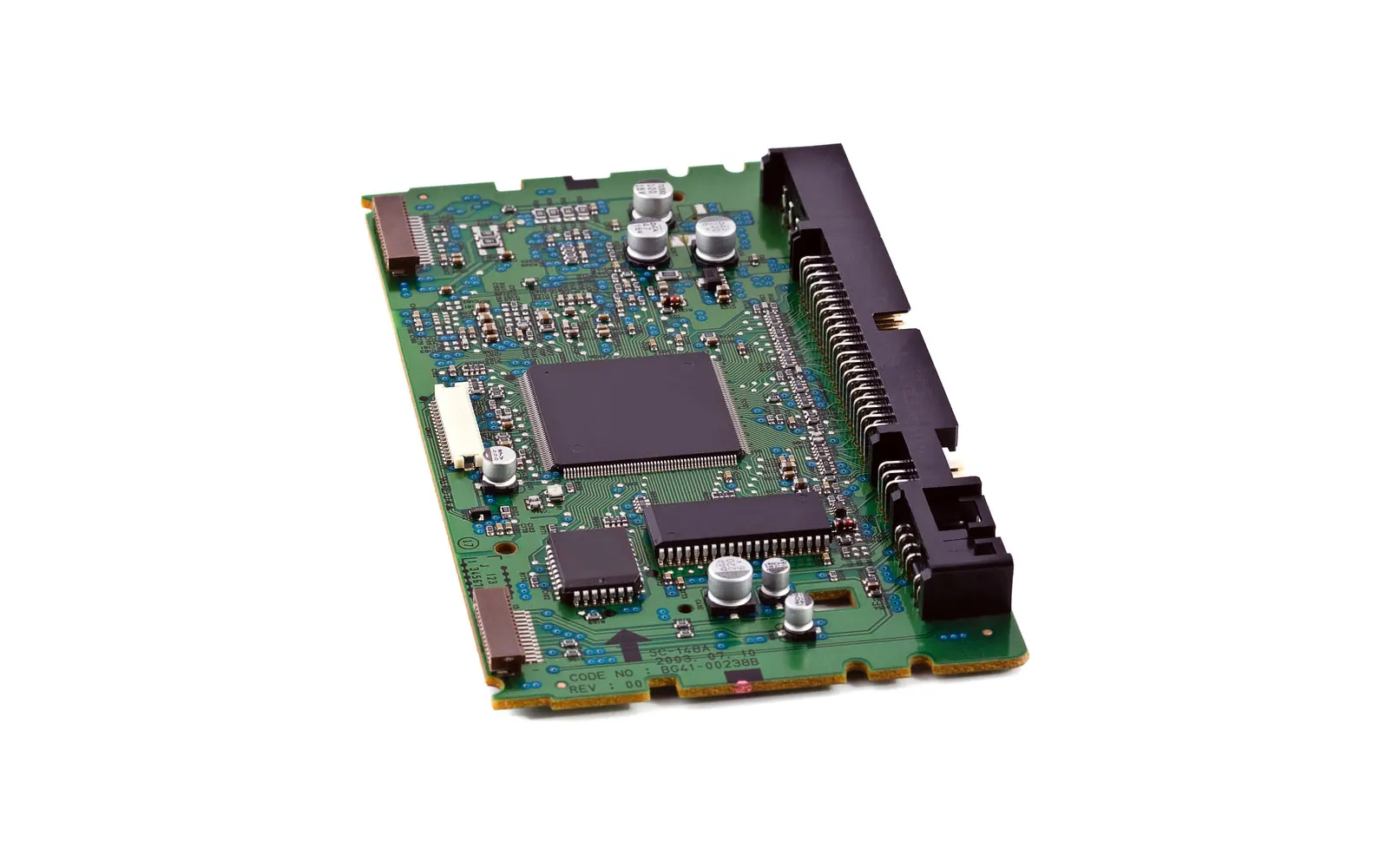

From Bare Board to Functioning Module: The PCBA

A PCBA (Printed Circuit Board Assembly) is what you get after components meet the board. It’s the point where theory turns into reality — when the bare PCB is populated, soldered, inspected, and comes alive as part of a larger system.

The process typically combines SMT (Surface Mount Technology) for miniature, high-density parts, and DIP (Dual In-line Package) soldering for components that require more mechanical strength. Depending on the product, these steps might happen on automated lines or involve manual fine-tuning for custom builds.

Testing begins at the PCBA stage, and this is where design flaws, thermal issues, or component mismatches usually surface. In short, PCBA is where the quality of every upstream decision gets revealed.

PCB vs. PCBA — A Practical Perspective

In manufacturing terms, the difference is simple:

-

PCB: a blank foundation — no components, no functionality.

-

PCBA: the finished, assembled, and testable board.

But in practice, the gap between the two is where most of the engineering happens. A perfect PCB design means little if the assembly process introduces stress, misalignment, or poor solder joints. That’s why collaboration between design and production teams is so critical.

Integrating Custom Wiring Harnesses

Few PCBAs operate in isolation. They often need to connect with sensors, motors, or other boards through custom wiring harnesses When designed properly, a harness doesn’t just connect — it stabilizes, protects, and simplifies the system.

From experience, three things tend to make or break a harness integration:

-

Electrical Compatibility – ensuring voltage and signal integrity across connections.

-

Mechanical Fit – routing cables cleanly through constrained spaces without strain.

-

Reliability – choosing materials that can survive vibration, heat, or repeated motion.

A good wiring harness can quietly save you hours of troubleshooting later — and a bad one can turn a solid PCBA into a field failure waiting to happen.

A Note from the Production Floor

The relationship between PCB and PCBA might look straightforward on paper, but in practice it’s where design meets reality. A clean schematic doesn’t guarantee a smooth build, and a well-built PCBA often reflects dozens of small engineering compromises that never make it into the documentation.

Understanding both stages — and how they interact — is what separates a functional product from a reliable one.

1. What products does Kaweei offer?

Kaweei specializes in custom PCBA wiring harnesses and solutions for PCB assemblies, providing high-quality design, assembly, and manufacturing services.

2. What is a custom PCBA wiring harness?

A custom PCBA wiring harness is designed to connect your PCBA and PCB modules reliably, ensuring optimal electrical performance, proper fit, and long-term durability.

3. How does Kaweei ensure the quality of custom wiring harnesses?

Kaweei conducts electrical testing, mechanical inspections, and stress tests on every custom PCBA wiring harness to guarantee performance, safety, and reliability.

4. Can Kaweei handle small and large PCB or PCBA orders?

Yes, Kaweei provides flexible production for both small-scale PCB/PCBA prototypes and large-volume custom PCBA wiring harness manufacturing, ensuring consistent quality at any scale.

5. How do I get a custom PCBA wiring harness from Kaweei?

Simply share your PCB and PCBA specifications, and Kaweei will provide a tailored custom PCBA wiring harness solution, from design and prototyping to full-scale manufacturing. Contact us anytime to discuss your project and get started.