High-Protection Integrated Control Harness for Snow Removal Machinery

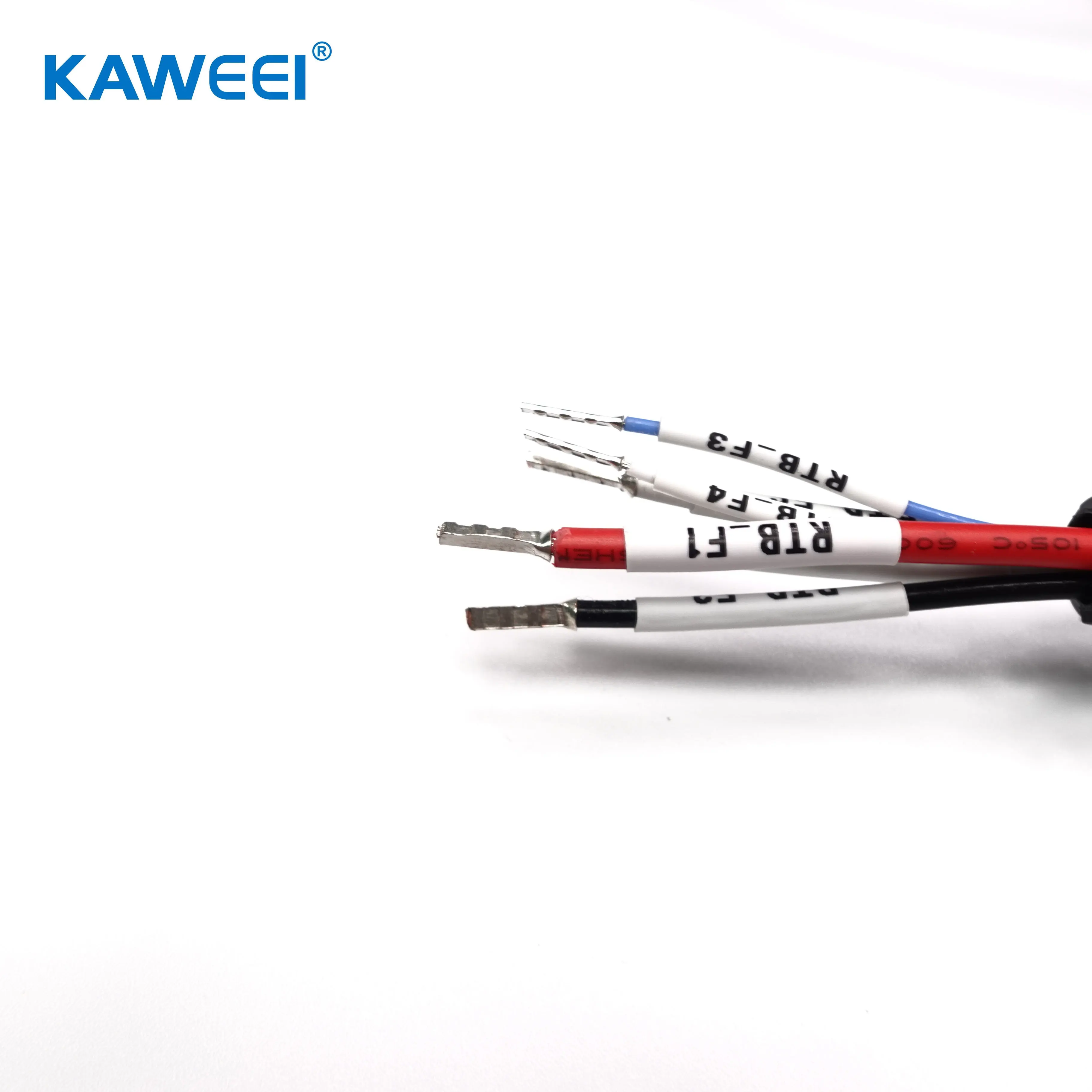

1.High-Protection Sealed Connector for Complex Working Conditions 2.Multi-Spec Connector Integration for Multi-Component Control 3.Dual-Layer Protected Wires for Durability 4.Labeled & Color-Coded Wiring for Efficient Maintenance

Ruggedized Wiring Solutions for Snow Removal Equipment

We engineer and assemble high-durability wire harnesses specifically for snow blowers and plows. Our solutions integrate power, control, and sensing lines into a single, weather-sealed assembly designed to survive harsh winter conditions.

| Design Feature | Technical Specification | Kaweei Integration Value |

|---|---|---|

| Sealed Connectivity | IP67/IP69K Waterproof Connectors | We source and assemble robust sealed connectors (e.g., Deutsch DT, Amphenol) to prevent salt water ingress and corrosion. |

| Cold Weather Resilience | Dual-Layer Protection (PVC/PUR) | We select wire jackets rated for -40°C flexibility to prevent cracking, adding an extra protective sleeve for abrasion resistance against ice. |

| System Integration | Multi-Spec Connector Hybrid | Combines high-current power lines (for starter/motor) and low-voltage signal lines (for sensors/lights) into one neat loom. |

| Maintenance Logic | Color-Coding & Hot Stamp Labeling | Every wire is distinctly identified, allowing mechanics to quickly trace circuits during field repairs or maintenance. |

| Vibration Proofing | Strain Relief & Locking Mechanisms | Custom molding or backshell assembly ensures connections remain secure despite intense engine vibration. |

Engineering for "Zero-Failure" in Winter

As a specialized custom wire harness provider, Kaweei addresses the critical failure points of outdoor power equipment:

- Material Selection: We don't manufacture the raw wire, but we strictly source automotive-grade (AVSS/TXL) or industrial cables verified for sub-zero flexibility.

- Process Quality: Automated crimping ensures gas-tight terminal connections that resist oxidation from snow and road salts.

- Custom Topology: We design the harness routing to fit your specific chassis, avoiding hot engine parts and moving augers.

Technical Specifications

| Wire Type | Single Core |

| Wire Gauge (AWG) | 18AWG+20AWG |

| Conductor Material | Tinned Copper |

| Outer Jacket Material | PVC |

| Voltage Rating | 24V |

| Temperature Rating | 105°C |

| Connector Type | TE HD36-24-18SN,MOLEX 39012021 |

| Applications | Automobile Applications |

Key Features

High Interference Immunity

Optimized twisted-pair structure maintains signal integrity even in complex electromagnetic environments.

High Flexibility

Special drag chain cable material resistant to repeated bending and torsion, with a service life exceeding 5 million cycles.

Vibration Proof

Special thread locking or latch mechanisms ensure connections remain secure even in high-vibration environments.

Multi-Certified

Products hold CE, UL, TUV, and other authoritative certifications, ensuring reliability for global markets.