Custom Battery Connector Harnesses for Safer

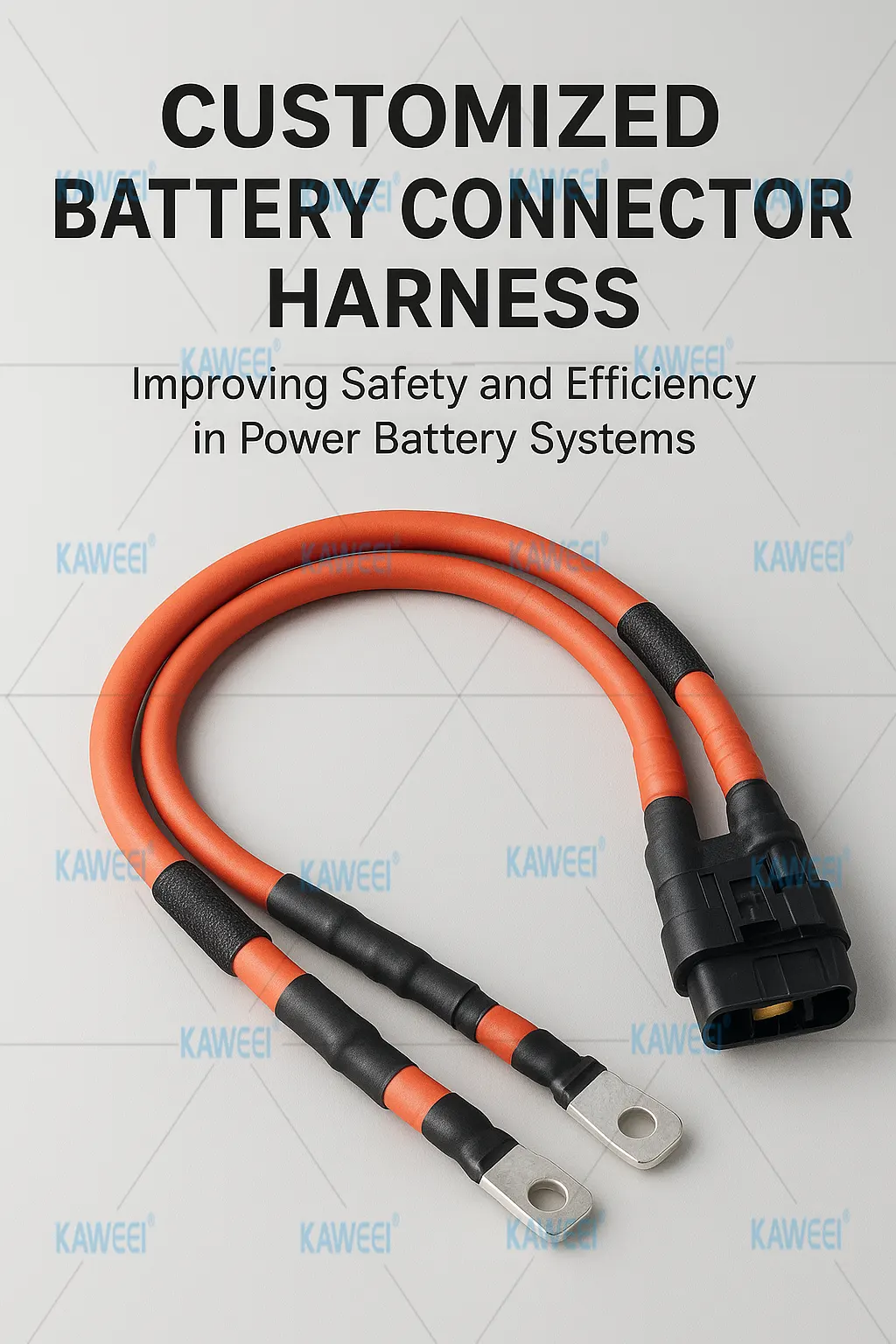

As a wiring harness development engineer, I have spent the past ten years working on power battery systems for new energy vehicles. Battery Connectors play a critical role in these systems, carrying high currents and directly affecting vehicle safety and performance. I would like to share some of my hands-on project experiences and how customized harnesses perform in real engineering scenarios.

Last year, I was responsible for the main high-voltage harness design in a power battery project for Client A. We encountered an issue where standard terminals reached temperatures above 50°C under a continuous 80A current, and heat dissipation was challenging within the compact battery pack. To address this, I recommended using silver-plated copper terminals and optimizing the crimping process, combined with 16mm² conductor wires. After these adjustments, contact resistance decreased by about 30%, current transmission stabilized, and heat generation was significantly reduced.

Moreover, the battery pack used a multi-module parallel design, and the original harness routing was complex and difficult to service. I proposed trimming the harness to the shortest possible path and designing fork terminals for each module. As a result, maintenance time per module was reduced from two hours to under one hour, and on-site wiring errors were noticeably decreased. This experience gave me a clear understanding of how customized design directly improves maintenance efficiency.

In Client B’s 2023 energy storage EV project, we faced a high-temperature, high-humidity, and high-vibration environment inside the battery compartment. To ensure reliability, I added flame-retardant sleeves to the terminals and designed sealed locking structures. After continuous high-temperature cycling and vibration testing, the harness maintained stable contact with no aging or failures. This reinforced my understanding of the reliability of customized harnesses in harsh environments.

From these projects, I concluded that in new energy vehicles, customized Battery Connector harnesses not only enhance high-current transmission safety but also improve system adaptability and modular maintenance efficiency. Compared with standard harnesses, customized solutions are better suited to compact layouts, high-load applications, and complex environments, making them critical to ensuring overall vehicle performance and safety.

Kaweei is a professional custom wiring harness manufacturer specializing in EV and energy storage systems.

We offer reliable, high-current harness solutions tailored to your needs.Contact us anytime。

Kaweei – Box Header Connector Cable FAQ

1. Q: What does Kaweei do?

A: Kaweei specializes in custom wiring harnesses, including battery connector harnesses, tailored for EVs and energy storage systems.

2. Q: Can Kaweei handle high-current or high-voltage applications?

A: Yes. We design harnesses to safely carry high currents and voltages, ensuring stable performance in demanding environments.

3. Q: How flexible is your customization?

A: Very flexible. We can adjust wire lengths, connectors, and layouts to meet your exact specifications.

4. Q: How do you ensure reliability?

A: Every harness is tested for temperature, vibration, and contact resistance. Protective sleeves and locking designs add extra safety.

5. Q: Do you support maintenance and troubleshooting?

A: Yes. Our modular, clearly labeled harnesses make maintenance easy, and we provide technical guidance when needed.