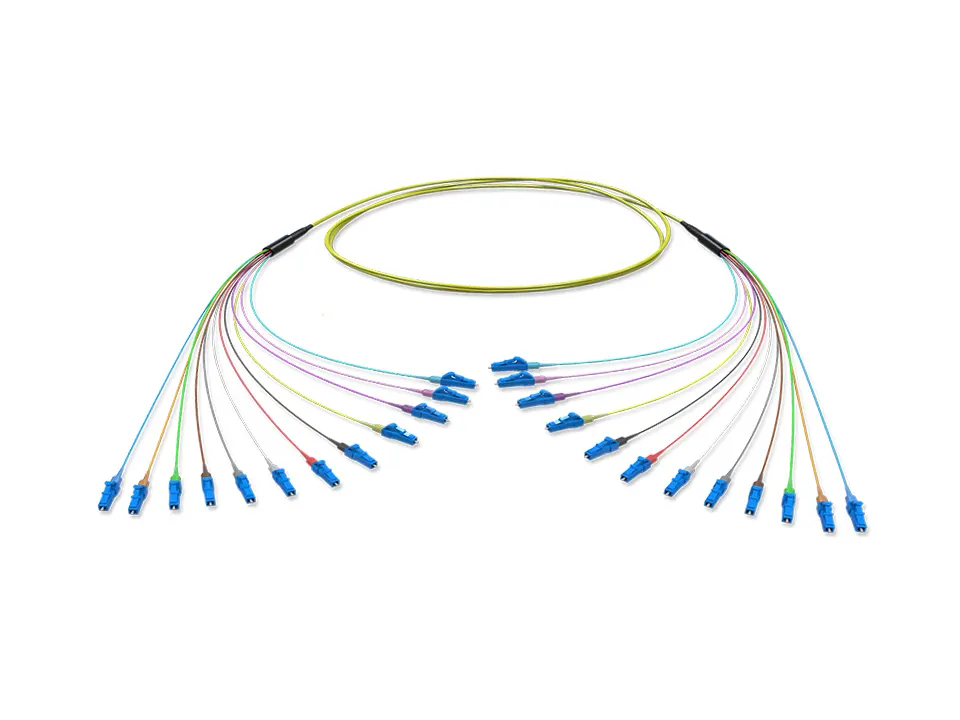

Custom Fanout Cable

With the rapid development of modern electronic devices, industrial automation systems, and new energy vehicles, the demand for high-density, multi-signal output solutions has increased significantly. The Fanout Cable has become a critical component in wiring systems, enabling multiple signals from a single trunk cable to be efficiently distributed to multiple connectors or sub-harnesses, greatly improving wiring efficiency and overall system reliability.

What is a Fanout Cable?

As the name suggests, a Fanout Cable is a cable structure designed to “branch” signals from a single trunk cable into multiple smaller connectors or sub-harnesses. It allows complex multi-signal lines to be centrally managed and neatly organized through branch design, achieving high-density wiring and modular management. Fanout Cables offer advantages such as space saving, improved installation efficiency, and reduced signal interference, making them widely used in industrial, medical, communication, and new energy applications.

Features of Fanout Cable

Compared with traditional cables, Fanout Cables not only save wiring space but also enhance signal transmission stability. Through shielding designs and precise manufacturing, each Fanout Cable effectively reduces electromagnetic interference, ensuring long-term reliable operation of devices and systems.

Applications of Fanout Cable

Fanout Cables have been widely applied across various industries:

-

Industrial Automation: PLC control systems, servo motor connections, and robotic flat wiring all require high-density, reliable signal distribution. Fanout Cables help keep wiring organized and make maintenance easier.

-

Medical Equipment: For probe signal distribution and module interconnections, Fanout Cables ensure high-precision signal transmission and stable operation of medical devices.

-

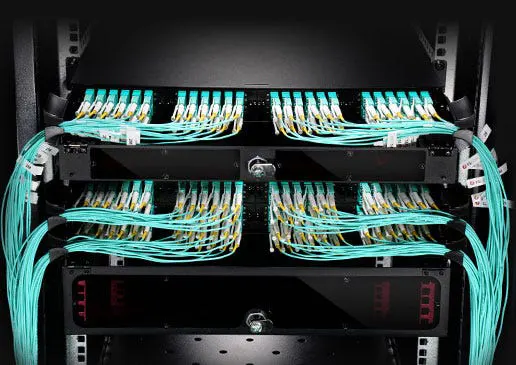

Communication & Networking: Fiber optic branching, test fixtures, and multi-interface wiring benefit from Fanout Cables by simplifying cable layouts, reducing maintenance efforts, and improving overall system efficiency.

-

New Energy & Automotive: Battery pack BMS branching, charging system wiring, and energy storage module cabling require high reliability and protection. Fanout Cables provide dependable performance to ensure system safety and stable operation.

Kaweei’s Custom Fanout Cable Solutions

As a professional wire harness manufacturer, Kaweei provides a wide range of custom Fanout Cable services, offering flexible design options based on client requirements:

-

Multi-core PVC/PU jacketed trunk cables with individually shielded sub-cables

-

Round or multi-channel designs branching to individual connectors

-

Support for various interface standards: DB, RJ45, M12, M8, Molex, JST, etc.

-

Customizable wire length, color, numbering, sleeving, and waterproof rating

Kaweei has a complete production management system and strict quality control process. Each Fanout Cable undergoes conductivity testing, tensile testing, and visual inspection before leaving the factory. Our products also comply with RoHS, REACH, ISO9001, and other international standards, ensuring reliable performance in diverse and demanding environments.

Kaweei is a professional wire harness manufacturer. For custom Fanout Cables or any wire harness needs, contact us anytime for reliable, tailored solutions.

FAQ:

1. What types of Fanout Cable customization does Kaweei offer?

Kaweei provides custom Fanout Cable solutions, including multi-core PVC/PU trunk cables with shielded sub-cables, multi-channel branches to individual connectors, and support for interfaces like DB, RJ45, M12, M8, Molex, and JST. We also customize length, color, numbering, sleeving, and waterproof rating.

2. Does Kaweei provide samples for Fanout Cable?

Yes. Kaweei can provide custom Fanout Cable samples for testing and validation before mass production. Samples can be made according to client drawings or specifications.

3. Are Kaweei’s Fanout Cables compliant with international standards?

Yes. Our Fanout Cables meet RoHS, REACH, ISO9001 standards and can support UL certification. Each cable is tested for conductivity, tensile strength, and appearance before shipment.

4. What is the minimum order quantity (MOQ) for custom Fanout Cable?

The standard MOQ is 10 units per model. For special designs or new tooling, MOQ may vary depending on project requirements.

5. How can I order custom Fanout Cable from Kaweei?

You can contact Kaweei’s engineering team directly. We provide full support from design and sample validation to mass production, ensuring every custom Fanout Cable meets your specifications.