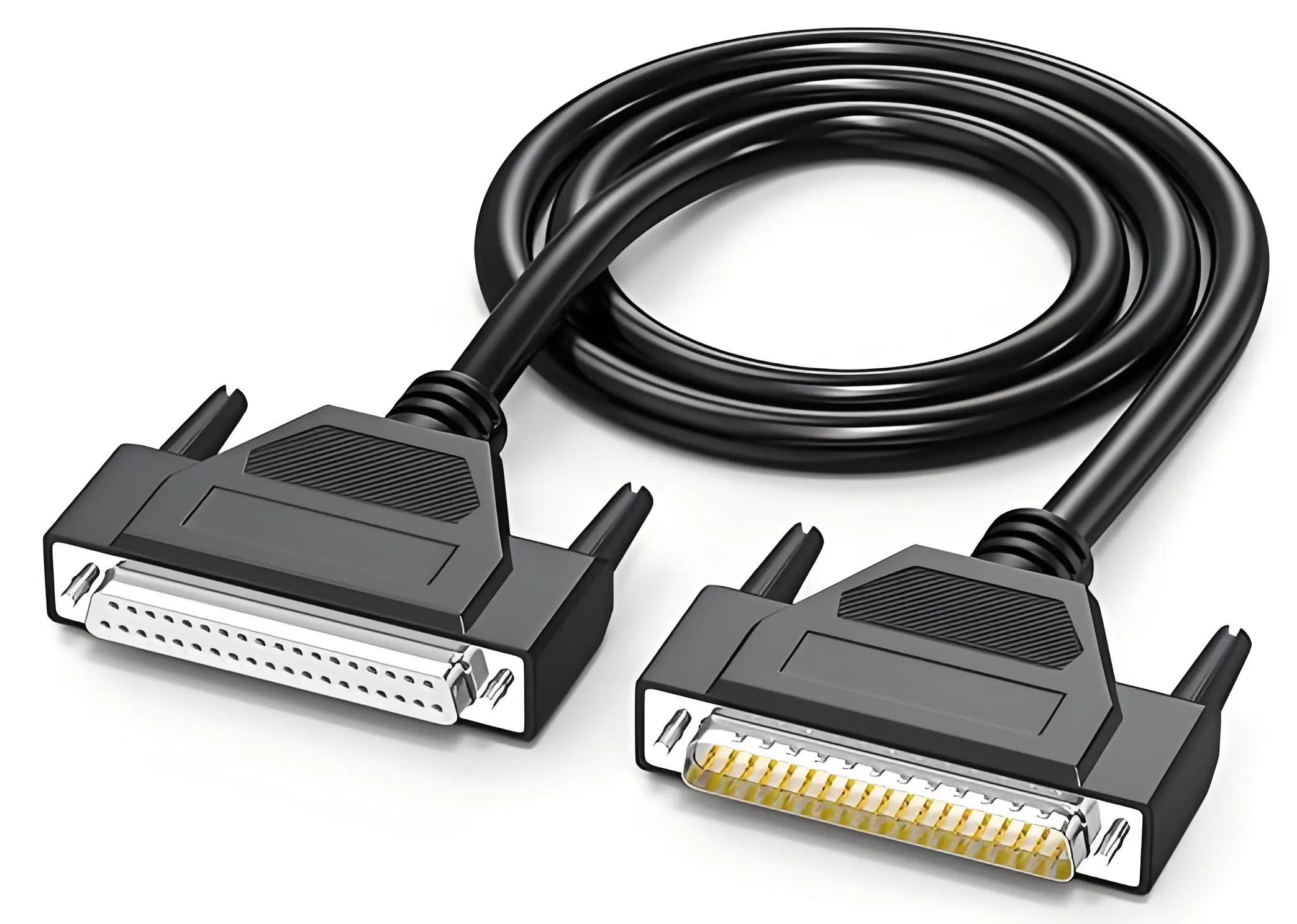

D-Sub Cable Assembly For Computer

Origin and Development: D-sub cables began to be widely used in the 1960s, mainly for data transmission between computers and external devices. With the continuous innovation and development of computer technology, D-sub cables have gradually become an important tool for connecting various electronic devices.

Definition: A D-sub cable is a connection cable that is commonly used for data transmission and signal transmission. It can transmit multiple types of signals, including analog signals, digital signals, and power signals.

Materials for D-Sub Cable:

- Conductor material: Copper, tinned copper.

- Insulation material: Polyester Expanding Braided Sleeving

- Shield materials: Braid shield

- Connector material: Standard D-SUB PBT, Black Solder, Zinc Alloy Shell(MH) + Screw

Structural features:

Cable: D-sub cables are usually composed of multiple wires, which are used to transmit different signals. In order to reduce signal interference, cables are generally shielded, such as adding a shielding layer. Common shielding materials include copper foil, braided net, etc.

Connector: The D-sub connector is trapezoidal and has different PINs and arrangements. Common ones include DB9, DB15, DB25, DB37, etc., to adapt to different application scenarios and signal transmission requirements.

Application fields

Computer field: It is commonly used to connect computer peripherals such as analytical equipment, monitors, printers, scanners, etc., to achieve data transmission and communication between computers and external devices.

Communication equipment field: used to connect various network devices, such as communication base stations,radios and other communication equipment to ensure the stable transmission of communication signals.

Industrial control field: In industrial automation production lines, D-sub cables are used to connect industrial control equipment such as sensors,inverters, etc., to achieve real-time data interaction and control command transmission between devices.

Medical equipment field: can be connected to medical equipment such as electrocardiographs, B-ultrasound, X-ray machines, monitors, etc., to transmit medical data and control signals, to ensure the accurate operation of medical equipment and the safe transmission of data.

Aviation electronic equipment field: inside the aircraft, D-sub cables are used to connect avionics equipment such as navigation systems, radars, communication equipment, etc., to ensure reliable communication and collaborative work between aircraft systems.

In practical applications, different devices and environments place varying demands on the length, connector type, pin configuration, and shielding method of D-sub cables. Therefore, customized D-sub cable assemblies are often the optimal choice to ensure reliable signal transmission and precise device interconnection in specific scenarios. Key considerations for customization include:

- Connector type and pin count: Select the appropriate D-sub variant (e.g., DB9, DB15, DB25) based on the equipment interface and signal requirements.

- Conductor and shielding materials: Choose copper or tinned copper conductors for optimal conductivity, paired with suitable shielding options such as copper foil or braided shields to ensure signal integrity and EMI/RFI protection.

- Cable length and jacket material: Define the required length according to the installation environment, and select outer jackets with abrasion resistance, high-temperature tolerance, or flame-retardant properties.

- Connector termination method: Depending on the application, adopt soldering, crimping, or overmolding techniques to guarantee mechanical strength and long-term reliability.

With years of expertise in wire harness manufacturing and customization, Kaweei delivers tailored D-sub cable solutions designed to meet diverse customer requirements. Whether for computer peripherals, industrial automation, medical devices, or aerospace electronics, Kaweei provides high-quality, durable, and dependable cable assemblies. Backed by a skilled engineering team and strict quality assurance processes, Kaweei ensures robust performance and secure data and power transmission across mission-critical applications.

FAQ 1: What can be customized in Kaweei D-sub cable assemblies?

Connector type, pin count, conductor/shielding materials, cable length, jacket, and termination method.

FAQ 2: How does Kaweei guarantee quality?

Strict ISO-certified production, 100% electrical testing, and durability verification.

FAQ 3: Where are Kaweei D-sub cables commonly used?

Computing, industrial automation, medical devices, and aerospace electronics.