IDC Connector For Custom Cable Assembly

IDC Connector stands for Insulation Displacement Connector.

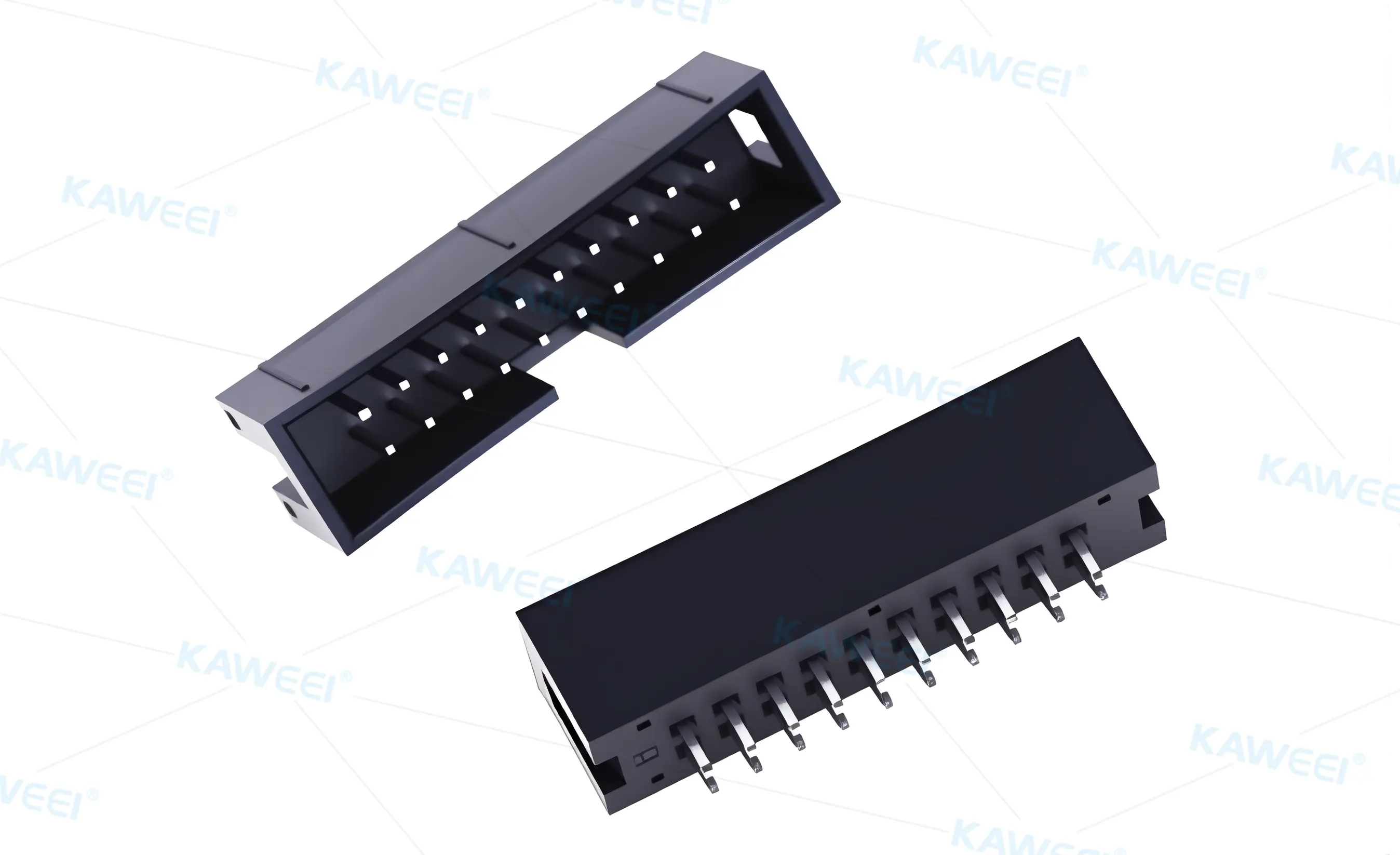

Structure of IDC Connector:

In simple terms, it relies on metal blades piercing through the wire insulation to directly contact the copper conductor — no stripping required.

- Plastic housing: Holds all parts in place, provides insulation, prevents short circuits, usually equipped with latching features.

- Metal blades: Shaped like a “V” or “U”, they cut through the insulation when pressed and lock onto the copper conductor; typically symmetrical on both sides for stronger retention.

- Wire slots: Guides for cable insertion; once pressed down, the connection is automatically established. Some designs feature a locking cover for additional security.

With the blades embedded in the housing, the wire only needs to be pressed into place to achieve a fast, stable, and reliable electrical connection.

Key Features of IDC Connector:

- Rapid termination: No stripping or soldering required, simple press-in assembly.

- Optimized for ribbon cables: Most commonly used with flat ribbon cables (e.g., IDE hard drive cables in computers).

- High reliability: Contact slots firmly grip the conductor, ensuring vibration resistance and minimizing contact failures.

Advantages of IDC Connectors:

- Fast installation: Eliminates the need for stripping and soldering, significantly improving assembly efficiency.

- Consistency: Ensures uniform termination depth and quality in mass production, reducing operator variability.

- High reliability: Metal blades penetrate insulation and clamp tightly onto the conductor, maintaining long-term stability against vibration and oxidation.

- Cost-effective: Reduces labor time and eliminates additional processing steps, ideal for volume manufacturing.

- High-density capability: Common in 1.27mm and 2.54mm pitch ribbon cables, enabling compact, multi-signal transmission in limited space.

Limitations of IDC Connectors:

- Strict requirements for conductor diameter and insulation thickness.

- Repeated mating/unmating may result in degraded contact performance.

- Poor termination quality can lead to short circuits or open circuits.

Kaweei Custom IDC Connector Harness Solutions:

- Custom IDE Ribbon Cables: Standard 40-pin interfaces, ensuring stable signal transmission.

- IDC Punch-down Network Cabling: Supporting Cat5e/Cat6, with precision terminations.

- Other custom solutions: LCD ribbon cables, industrial control harnesses, and more.

With professional crimping technology, rigorous quality testing, and both prototype and mass production capabilities, Kaweei delivers reliable and tailored IDC harness solutions.

Kaweei IDC Connector Customization – FAQ

Q1: What IDC cables can Kaweei make?

A1: We provide IDE ribbon cables, network IDC punch-down cables (Cat5e/Cat6), LCD ribbon cables, and industrial control harnesses.

Q2: Can I choose pin count and cable length?

A2: Yes, we support full customization of pins, pitch, and cable length.

Q3: How does Kaweei ensure quality?

A3: All products are made with professional press-in tools and tested for continuity, strength, and stable signal transmission.

Q4: Where are IDC cables used?

A4: They are used in computers, networking, consumer electronics, and industrial equipment.

Q5: Do you offer samples and bulk orders?

A5: Yes, we provide both prototypes for testing and mass production.