How to Choose the Right Wiring Harness Manufacturer?

In mechanical equipment, medical devices, automation systems, and communication equipment, complex electrical connections place higher demands on wire harness design and quality.

Standard cables often fall short when it comes to customized layouts or performance needs. In such cases, a professional wire harness manufacturer is essential — one that can provide high-quality, precisely tailored harness solutions to ensure reliable and efficient system operation.

Therefore, selecting the right wire harness manufacturer is critical.

It directly affects product reliability and service life, as well as the overall efficiency of system integration and delivery schedules.

So, how can businesses effectively and wisely choose the right supplier from so many options?

Choosing a wire harness manufacturer is a decision that requires a careful balance of quality, cost, service, and technical capability.

1. Clearly Define Your Wire Harness Requirements:

- Application Field:Automotive, home appliances, industrial machinery, medical devices, or aerospace?Each industry has its own set of standards — such as waterproofing, high-temperature resistance, or EMC shielding.

- Technical Specifications:Voltage/current ratings, wire types (e.g., UL-certified, flame retardant), connector brands (e.g., Molex, TE Connectivity), and protection levels (IP67/ IP68, etc.).

- Production Volume:Is it small-batch customization or large-scale mass production?Can the manufacturer support flexible production models like JIT (Just-In-Time) delivery?

2. Evaluate the Manufacturer’s Certifications:

- Quality Management Systems:Look for ISO 9001 or IATF 16949 (for automotive); ISO 13485 (for medical).Also check for product safety and compliance certifications like UL, CE, RoHS, and whether they follow IPC/WHMA-A-620 international assembly standards.

- Product Consistency:Does the manufacturer implement strict quality control procedures (e.g., first-article inspection, full or sample inspection)?Is there a traceability system and documentation in place?

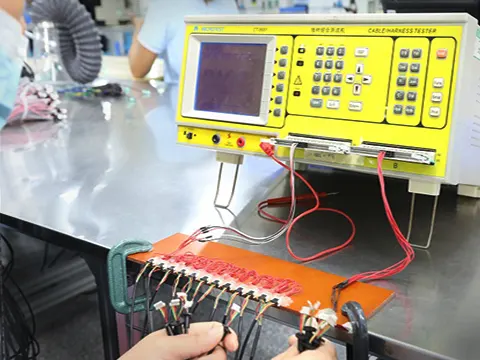

- Testing Capabilities:Do they have the necessary equipment (e.g., hi-pot testers, continuity testers)?Can they perform function tests, dielectric withstand tests, or other key verifications?

3. Delivery Time and Production Capacity:

- Production Scale: Can the manufacturer handle mass production and meet your order volumes?Is there capacity flexibility for urgent or large-scale orders?

- On-Time Delivery: Do they have a track record of meeting delivery timelines?Can they offer quick prototyping or sample services?

- After-Sales Support: Do they provide harness installation guidance or fault analysis reports?

4. Cost and Pricing Transparency:

- Reasonable Quotation:Is the pricing structure clear?Can the manufacturer break down material and labor costs transparently, while also helping to reduce costs without sacrificing quality?

- Long-Term Pricing Mechanism:Do they offer options like annual pricing, discounts on long-term orders, or volume-based pricing strategies?

5. Service and Communication:

- Pre- and Post-Sales Support:Are there dedicated engineers or project managers available to support you?How quickly can they respond to issues and provide solutions?

6. Location and Logistics:

- Shipping Capability:Do they have export qualifications, customs clearance experience, and the ability to manage international shipments?

Choose Kaweei — Choose Reliable Connections

Choosing a wire harness is about choosing dependable connections.

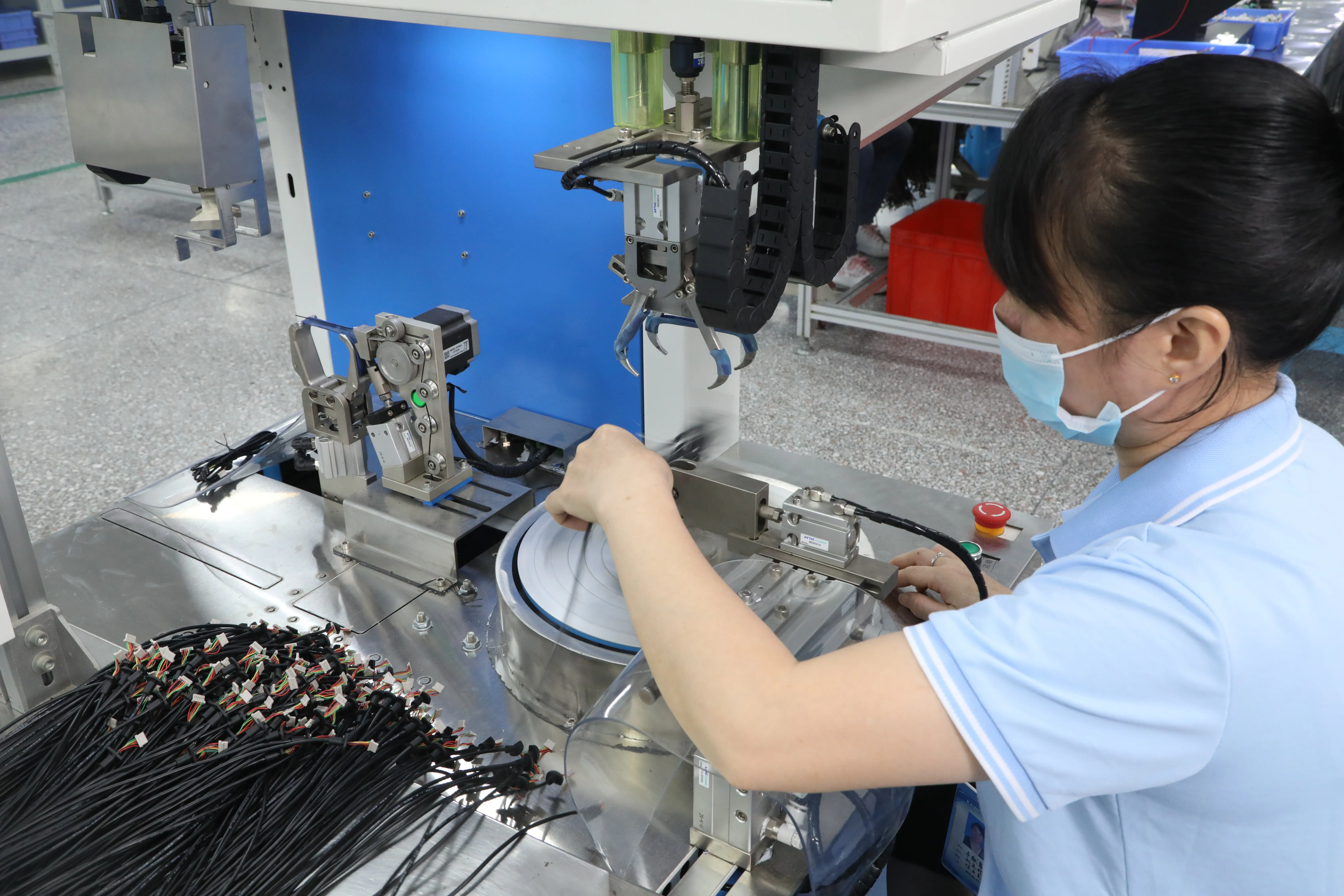

Kaweei, as a professional wire harness manufacturer, specializes in high-quality custom harness solutions.

With a well-established production system, strict quality control, and deep industry experience, we serve a wide range of sectors.

Whether you're building complex industrial machinery, precision medical devices, or high-standard automotive and telecom systems — Kaweei delivers efficient, reliable, and tailor-made wire harnesses to meet your needs.

We are your trusted long-term partner for cable solutions that power your products forward.

Wire Harness Manufacturer FAQ:

1. What industries does Kaweei serve with its wire harness solutions?

Kaweei provides customized wire harness solutions across a wide range of industries, including automotive, industrial automation, medical devices, consumer electronics, and telecommunications.

Each harness is tailored to meet the specific technical, safety, and regulatory requirements of your application.

2. Can Kaweei support low-volume prototyping as well as mass production?

Absolutely. Kaweei offers flexible production capabilities — from quick-turn prototypes and small batches to high-volume manufacturing.

We also support Just-In-Time (JIT) delivery and are ready to scale with your product from development to full-scale production.

3. What quality standards and certifications does Kaweei follow?

Kaweei is certified to ISO 9001 and complies with industry-specific standards such as IATF 16949 (automotive), ISO 13485 (medical), and IPC/WHMA-A-620 for cable assembly quality.

We also ensure our components and final products meet UL, CE, and RoHS compliance where applicable.

4. How does Kaweei ensure product reliability and consistency?

We follow a strict quality control process, including first-article inspection, in-process quality checks, and 100% final testing (such as continuity and hi-pot tests).

All materials and assemblies are fully traceable, ensuring product consistency, reliability, and accountability.

5. Can Kaweei support international clients and export needs?

Yes. Kaweei has rich experience in global logistics, including international shipping, export documentation, and customs clearance.

We provide bilingual communication, responsive engineering support, and fast service to meet the needs of clients worldwide.