Wired Test for Custom Wire Harnesses

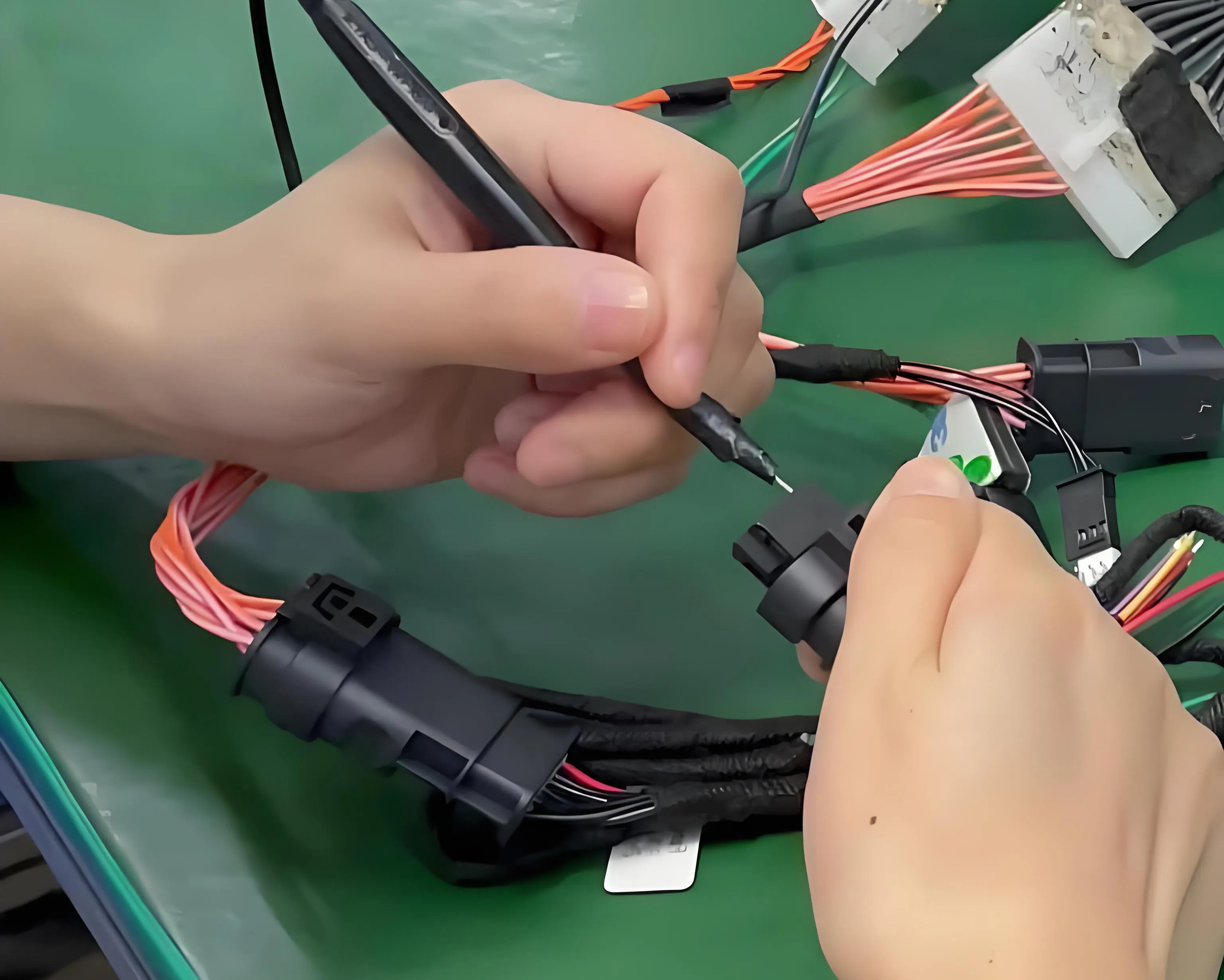

The quality of wire harnesses and wiring assemblies directly impacts product safety and reliability. As a wire harness manufacturer, it is essential to adhere to high standards in production and testing. How should Wired Test be conducted to ensure the quality of wire harnesses?

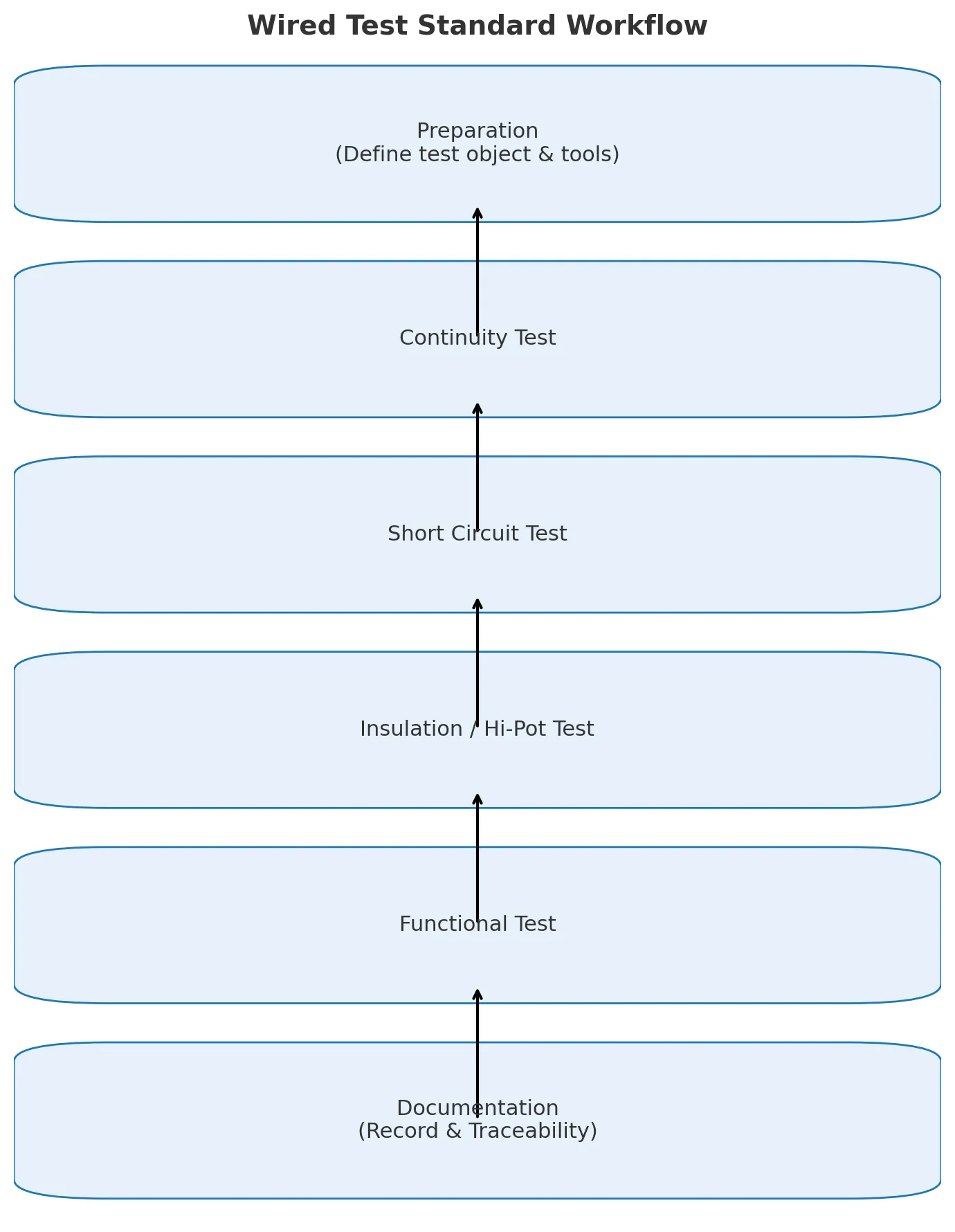

1. Preparation Phase

- The first step of Wired Test is thorough preparation:

- Identify the test subject: This includes finished wire harnesses, wiring assemblies, control cabinets, etc.

- Prepare testing equipment: Commonly used instruments include multimeters, wire harness testers, insulation resistance testers, and high-voltage testers.

- Determine test points: Refer to circuit diagrams or wiring schematics to identify the test locations for each conductor and connection point, ensuring comprehensive and accurate coverage.

- Each wire harness must undergo strict preparation before leaving the factory, ensuring that the test subject matches the design schematics exactly.

2. Continuity Test

- Continuity testing is used to verify the correct connectivity of conductors:

- Use a wire harness tester or multimeter to check the continuity of each wire.

- Identify any open circuits or miswiring issues.

- Automated testing equipment is employed to perform continuity checks on each harness, minimizing human error and ensuring that the harness will not cause operational failures due to connection problems.

3. Short Circuit Test

- Short circuit testing is primarily conducted to detect abnormal connections within the harness or between different circuits:

- Ensure that no unintended electrical connections exist between circuits.

- Check the integrity of wire insulation to prevent accidental contact between conductors.

- High-precision short circuit testers are used in production to identify potential risks at multiple levels, ensuring the electrical safety and stability of the harness.

4. Insulation Resistance / Hi-Pot Test

- In high-reliability industries such as automotive, aerospace, and medical equipment, wire harnesses must exhibit excellent insulation performance:

- Apply high voltage between conductors and between conductors and shielding or housing.

- Detect any dielectric breakdown, leakage, or insulation failure.

- Wire harnesses are subjected to strict high-voltage standards during insulation testing, ensuring reliability under high-voltage and complex operational environments.

5. Functional Test

- Functional testing is conducted with power applied or in a simulated operational environment:

- Verify that the harness and wiring assemblies function according to design specifications.

- Check electrical performance such as current-carrying capacity and signal transmission.

- By simulating real-world operating conditions, each wire harness is confirmed not only to meet design schematics but also to perform reliably in customer equipment over the long term.

6. Documentation and Traceability

- High-standard testing must be accompanied by comprehensive documentation:

- Record all test data, including resistance, insulation values, and test duration.

- Generate detailed test reports for quality traceability and after-sales support.

- A complete data traceability system is established, providing customers with reliable quality assurance and service support.

Wired Test Faq:

Q: What is Kaweei’s Wired Test?

A: Kaweei tests each custom wire harness for continuity, short circuits, insulation, and proper functionality to ensure safety and reliability.

Q: Why is Wired Test important?

A: Wired Test ensures harnesses are correctly wired, insulated, and safe to use, especially in high-reliability industries like automotive and medical.

Q: How are test results recorded?

A: Kaweei records all test data and generates reports, providing full traceability and quality assurance for every harness.