Integrated Multi-Interface Snow Blower Control Wiring Harness | Aviation Plug & Sensor Connectivity

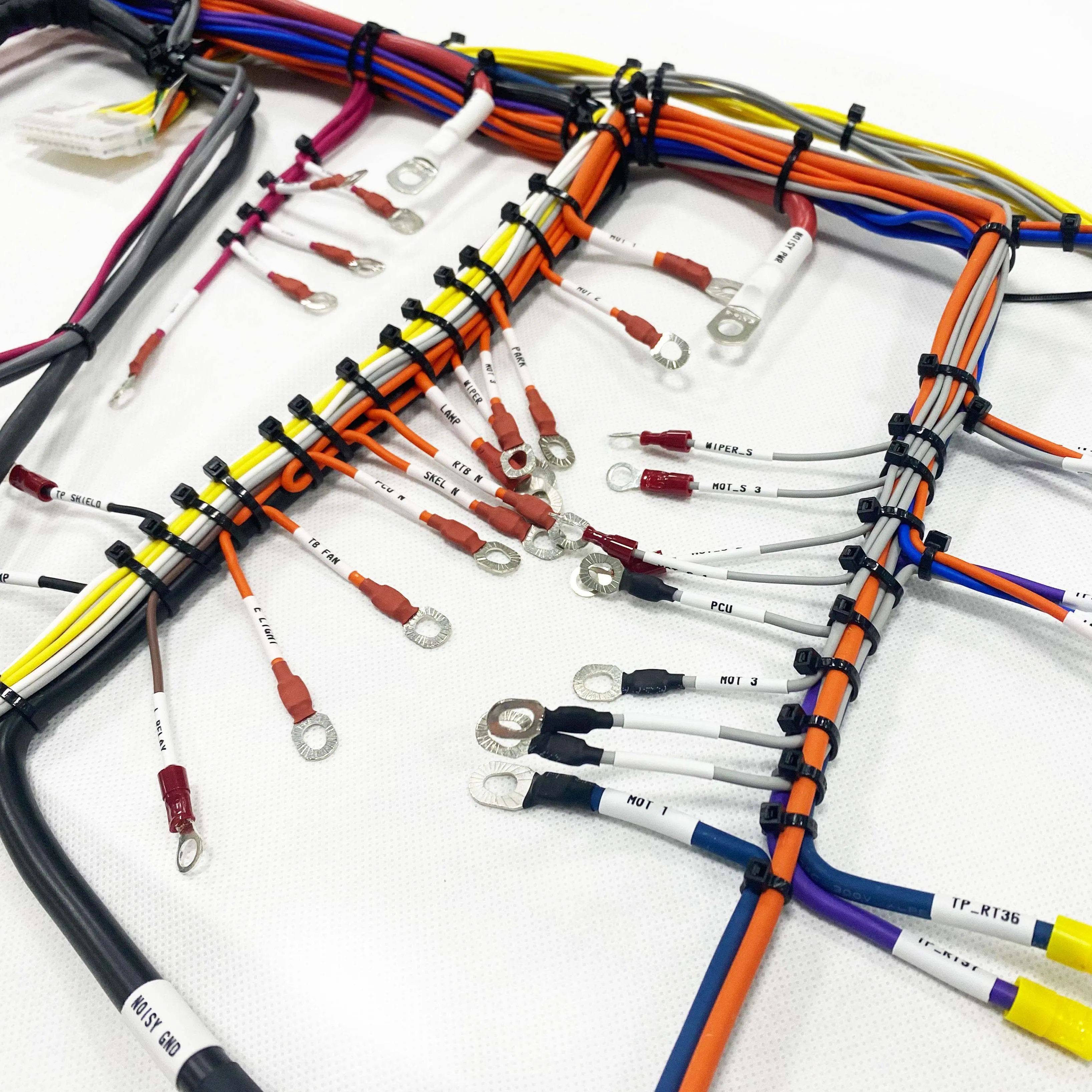

This specialized custom cable assembly is engineered to centralize the electrical system of industrial and consumer snow blowers. By integrating rugged aviation plugs with multi-specification terminals into a single harness, it enables simultaneous connection of power modules, control panels, and snow detection sensors. Designed for extreme cold and high-vibration environments, this "All-in-One" solution simplifies internal routing, reduces assembly time, and enhances the reliability of winter machinery operations.

Integrated Wiring Solutions for Snow Removal Equipment

We provide unified cable assembly solutions for snow blowers, replacing messy individual wires with a single, ruggedized harness. Our design focuses on cold-weather performance and high-vibration connectivity.

| Assembly Interface | Connection Type | Kaweei Integration Value |

|---|---|---|

| Main Control Interface | Circular Aviation Plugs (GX16/GX20 or Military Spec) | Vibration-proof locking connectors ensure continuous operation during heavy snow clearing and engine vibration. |

| Sensor Integration | Waterproof Multi-spec Terminals | Seamless connection to snow depth sensors, chute rotation motors, and LED lighting systems. |

| Wire Material | Low-Temp PVC / PUR / Silicone | We select wire grades rated for -40°C to prevent jacket cracking and stiffness in freezing conditions. |

| Protection | Nylon Braided Sleeve / Corrugated Tube | Enhanced abrasion resistance against moving mechanical parts and ice debris. |

| Logic Design | "One Harness" Architecture | Consolidates Power, Signal, and Ground lines into one neat assembly for faster manufacturing installation. |

Engineering for Extreme Winter Conditions

As a specialized wire harness solution provider, Kaweei solves the unique challenges of outdoor power equipment:

- Cold-Start Reliability: We source components and wires specifically tested for flexibility in sub-zero temperatures, preventing brittle failures.

- Custom Pinout Logic: We engineer the breakout points to match the exact physical layout of your snow blower's chassis, ensuring easy routing to the engine, dashboard, and auger housing.

- Sealed Connections: Integration of IP67/IP68 rated connectors to prevent melted snow and moisture from corroding electrical contacts.

Technical Specifications

| Wire Type | Single Core |

| Wire Gauge (AWG) | 8AWG+10AWG+12AWG+16AWG+20AWG |

| Conductor Material | Tinned Copper |

| Outer Jacket Material | PVC |

| Temperature Rating | 105°C |

| Connector Type | DEUTSCH HD34-24-18PN ,APTIV 8-PIN MAL |

| Applications | Automobile Applications |

Key Features

Wide Temperature Range

Designed for -40°C to +105°C, ensuring stable operation from freezing outdoors to high-temperature workshops.

Easy Installation

Standardized interface dimensions support quick assembly and disassembly, reducing on-site maintenance costs.

Eco-Friendly

All materials comply with RoHS 2.0 and REACH directives; halogen-free and non-polluting to the environment.

Multi-Certified

Products hold CE, UL, TUV, and other authoritative certifications, ensuring reliability for global markets.