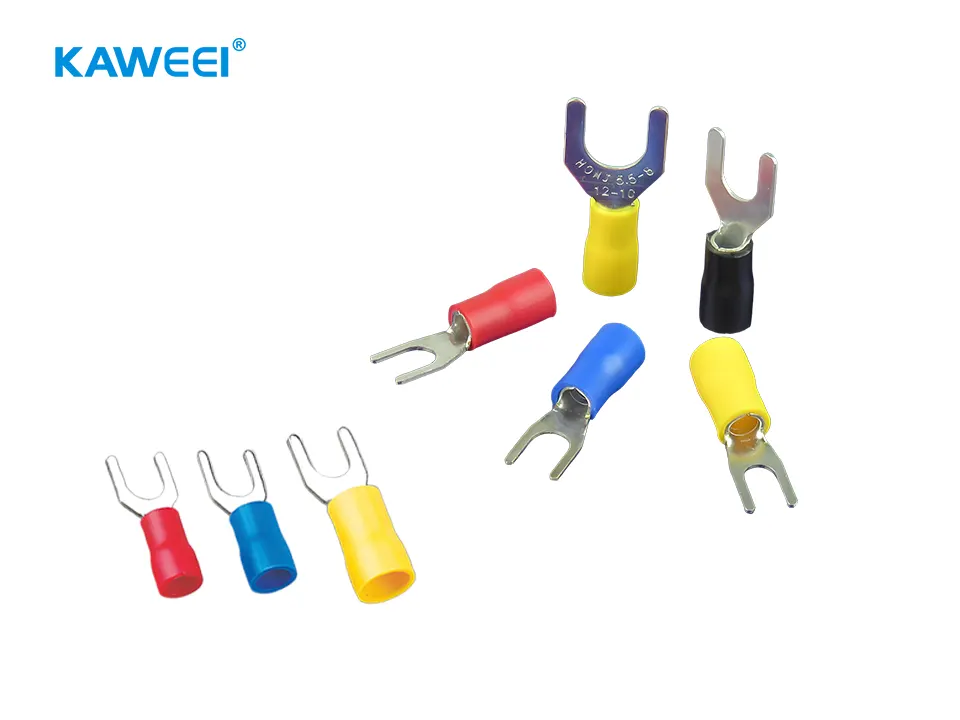

What is Spade Connectors?

Having spent years in wire harness development, I’ve come to a profound realization: the seemingly inconspicuous connectors often play a critical role in long-term system reliability. Today, I want to share some insights based on our team’s experience in several automotive and industrial control projects, focusing on a “small component” – the Spade Connector. It’s more than just a connector; it’s an extension of our design philosophy.

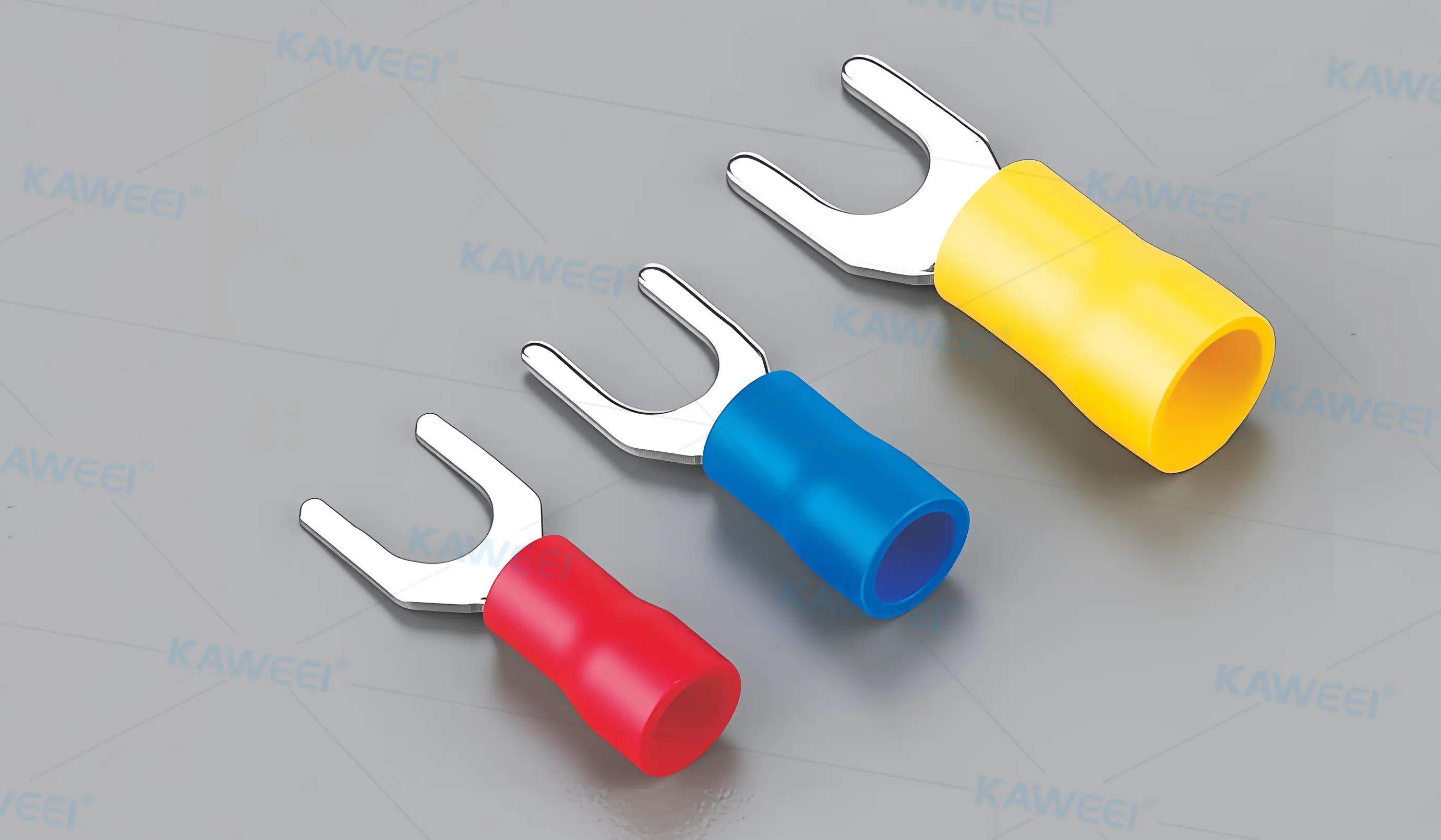

1. More Than a “Fork”: Rethinking Spade Connectors

Spade connectors, also known in the industry as fork terminals, are defined by their fork-shaped tongue that can “slide under” a screw or bolt. Don’t underestimate this simple Y-shaped structure: it significantly improves installation efficiency on-site. Engineers don’t need to completely remove the bolt; a few turns are enough to slide in the terminal and tighten it again. This advantage is especially evident in high-volume assembly or tight spaces.

Material selection sets the baseline for performance. Our team pays attention to two key points:

-

Base Material Conductivity: We prioritize T2 copper to ensure low-resistance current paths.

-

Surface Treatment: Tin plating is a cost-effective anti-oxidation solution. In our salt spray tests, tin-plated copper maintained its metallic color after 96 hours, whereas bare copper was already heavily corroded. For higher-demand applications, we consider silver or nickel plating.

Depending on the environment, we choose between bare terminals, pre-insulated terminals (PVC sleeves), and heat-shrink terminals. For example, in high-temperature, high-vibration areas like engine compartments, we always add heat-shrink tubing for secondary insulation and stress relief.

2. Practical Value in Projects: Balancing Efficiency and Reliability

Theory is one thing, practice is another. Here’s how spade connectors have solved real problems in our projects:

-

Assembly Efficiency – Measurable Gains

In last year’s automotive instrument panel harness project, we compared spade connectors to traditional bare-wire looping. Our measurements showed that using spade connectors reduced average connection time per point by about 18%, translating to significant labor savings and smoother production line cycles. -

Stable Electrical Performance – Data Speaks

Contact resistance is critical. We sampled terminals from multiple suppliers and found that high-quality tin-plated terminals stabilized at 3–4 mΩ initially. On a 10 A load, 4 mΩ means 0.4 W power loss, whereas 10 mΩ increases to 1 W. Long-term, this extra heat accelerates aging and can create safety risks. Internally, we have a strict “red line”: any sampled point exceeding 10 mΩ triggers a full batch return. -

Future-Proof Maintenance

Unlike soldered connections, spade connectors are pluggable. During the debugging phase, module replacement is routine. A connector that can be removed without damage avoids wire cuts or re-soldering, saving time and reducing cable wear – a big advantage for after-sales service. -

Environmental Adaptability – Choose Wisely

From dry household appliance enclosures to high-temperature engine compartments and humid industrial sites, spade connectors can perform if properly “dressed.” For instance, in an outdoor control cabinet project, we initially used ordinary PVC-insulated terminals, which became brittle and cracked after six months in humid, sulfurous air. Switching to weather-resistant nylon-sleeved terminals solved the issue.

3. Lessons Learned: Using This “Tool” Correctly

Even the best components fail if misapplied. Here are some hard-earned rules from our experience:

-

Precise Matching is Key

Current is king, wire gauge is queen. Choose terminal specs based on the conductor’s actual cross-sectional area (AWG or mm²) and expected maximum working current. We once didn’t update terminals when a wire gauge changed from 18 AWG to 16 AWG, leading to insufficient crimping and loosening during vibration tests.

Also, don’t overlook bolt size. The fork opening must match the screw diameter perfectly; too tight or too loose introduces hidden risks. -

Crimping Technique is Lifeline

Half the performance comes from proper crimping. We mandate using controlled crimp tools and periodically inspect crimp cross-sections. A proper crimp ensures all copper strands deform plastically, forming a “cold weld” without damaging the conductor. Using pliers or hammering flat is strictly prohibited. -

Standardize Torque

Bolts aren’t “the tighter, the better.” We specify recommended torque for each terminal type (e.g., M4 bolts: 1.2–1.5 N·m). Over-tightening deforms the fork and damages contact surfaces; under-tightening fails to provide adequate contact pressure, raising resistance under vibration. -

Treat Environmental Tests as the “Gold Standard”

For automotive and industrial products, vibration and thermal cycling tests are critical. We require that the change in contact resistance for all key spade connectors not exceed 10% after testing.

4. Two “Pits” That Made Us Smarter

Case A: Abnormal Temperature in a Lighting Circuit

During front headlight harness road testing, one spade connector ran nearly 15 °C hotter than ambient. Investigation showed that wiring layout changes induced resonance under vibration. A simple crimp was insufficient. We resolved it by adding wire clips to shift the resonance frequency and switching to terminals with a secondary locking structure.

Case B: “Chronic Issue” in a Humid Workshop

An industrial control cabinet initially used bare terminals to save costs. Installed in a southern coastal workshop, multiple terminals suffered electrochemical corrosion within six months, increasing contact resistance. The lesson: in humid or salt-spray environments, insulation (especially fully heat-shrink covered terminals) is not just for insulation – it’s a barrier against corrosion.

Kaweei – Custom Wire Harness & Spade Connector FAQ

1. What does Kaweei specialize in?

Kaweei designs and manufactures custom wire harnesses for automotive, industrial, and appliance applications. We focus on small to medium production runs where reliability, fit, and clean assembly matter most.

2. Can you make wire harnesses with Spade Connectors?

Yes. We build harnesses using Spade (fork) terminals in sizes from 0.5 mm² to 6 mm², with bare, tin-plated, or insulated options. Each harness can be customized for wire length, color, and insulation type.

3. How do you make sure the connection is reliable?

We use controlled crimping tools and test every harness for continuity and pull strength. Random samples go through vibration and thermal cycle tests to check for stable contact resistance.

4. What kind of projects use Spade Connector harnesses?

They’re common in control boxes, dashboards, machinery wiring, and HVAC units—anywhere a quick, secure screw-terminal connection is needed.

5. Can you help with design or prototypes?

Of course. Send us your drawings or samples, and our engineers can suggest better connector options or wire specs. We usually turn around prototypes in a few days before moving to full production.

Need a custom wire harness or Spade Connector solution?

Kaweei’s engineers are ready to help — contact us anytime for technical support or a quick quote.