USB Type-C Wire Harness Design: 1.2 Specification Analysis & Manufacturing Craftsmanship

For the past decade, the wire harness industry's understanding of USB has mostly remained in the era of "four wires (VBUS, D+, D-, GND)". However, with the widespread adoption of the USB Type-C™ specification (specifically version 1.2), the nature of our work has fundamentally changed. Type-C is not just a change in connector shape; it transforms the cable from a passive "wire" into an "active component" capable of intelligent communication.

Based on the latest USB Type-C specification, I have compiled the following design insights, hoping to provide a reference for wire harness design and manufacturing in the industry.

1. Physical Challenges: High Density and Miniaturization

The first impact of Type-C is physical. The specification clearly states the receptacle system height is under 3mm, which means tolerance control in **Connector Termination and Over-molding** must be extremely rigorous.

-

Design Insight: Previously with Standard-A, solder joint spacing was large, and fault tolerance was high. Now, the Type-C Pitch value is extremely small, challenging the Hot Bar soldering process. Meanwhile, to ensure the plug achieves over 10,000 insertion cycles in both "reversible" orientations, terminal elasticity and plating wear resistance have become key focuses in Incoming Quality Control (IQC).

2. Pinout Reconstruction: More Than Just Swapping Wire Order

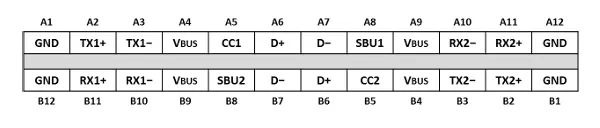

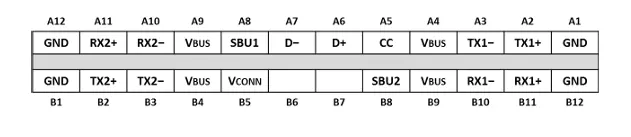

The most fascinating yet headache-inducing features of Type-C are the Reversible Plug and Bi-directional Insertion. This is not simple physical symmetry, but relies on complex pinout mapping.

(Note: Please focus on the symmetrical contact layout of the top and bottom rows of the receptacle)

(Note: Notice that only one CC pin is connected in the plug, which is critical in wire harness manufacturing)

-

Key Wire Harness Design Points:

-

Signal Integrity (SI): As seen in the figure, TX/RX are diagonally symmetrical. In Full-Featured Cable design, we must strictly control Differential Impedance (90Ω) and Intra-pair Skew. To support future frequency expansions, the processing of the **Shielding** (e.g., braiding density, aluminum foil wrapping) directly determines EMI test success.

-

SBU Pins: Sideband Use pins (SBU1/SBU2) are reserved for audio or Alternate Modes. These two wires cannot be ignored in non-standard wire harnesses, otherwise, some docking station functions will fail.

-

USB 2.0 Specifics: The specification notes that Type-C cables only need to implement one set of USB 2.0 D+/D-. This means that although the receptacle has two sets of D+/D-, we only need to wire one set, while the other set is shorted internally at the receptacle end or handled via logic.

-

3. CC Channel

If VBUS is the blood vessel, then the Configuration Channel (CC) is the nerve. It determines:

-

Connection Detection: Tells the host "I am plugged in".

-

Orientation Identification: Tells the device "Am I right-side up or upside down", determining which differential pair carries data.

-

Power Negotiation: Decides whether to use 5V/500mA or high voltage/high current PD protocols.

-

Engineering Warning:

During wire harness continuity testing, checking the resistance values (Ra/Rd/Rp) of the CC line is crucial.-

Introduction of VCONN: The spec indicates that the CC pin in the plug NOT connected through the cable will be redefined as VCONN. This means we need to design a circuit on the plug PCB to draw power from the host (VCONN) to drive the E-Marker chip within the cable. This is no longer a pure copper wire, but a system with a power supply loop.

-

4. Power Delivery

Type-C is extremely aggressive in power delivery. It defines VBUS current levels:

-

Default (500/900mA)

-

1.5A

-

3.0A

-

5.0A (Requires PD and E-Marker)

-

-

Wire Gauge (AWG) Selection: Standard Type-C cable assemblies are rated for 3A. If a client requests support for 100W (20V/5A) or higher, we must use wire rated for 5A. This directly leads to a thicker cable Outer Diameter (OD) and reduced flexibility. How to maintain cable flexibility while passing the Temperature Rise Test (usually requiring terminal temp rise not to exceed 30°C) is a focal point of contention between structural engineers and cable engineers.

-

Voltage Drop Control: Since VBUS may carry high current, the loop resistance (IR Drop) of VBUS and GND must be strictly calculated, and if necessary, ground shielding must be added as a return path.

Selection Insight:

-

5. E-Marker and Compliance

All USB Full-Featured Type-C cables are Electronically Marked cables.

-

Manufacturing Process Change:

Previously, we only needed to make physical connections (Soldering/Crimping). Now, when producing full-featured cables, we must solder an E-Marker Chip onto the plug PCB, power it via VCONN, and program information via BMC Communication on the CC line.-

Testing Phase: Production line test equipment must add E-Marker reading steps to verify if the cable correctly advertises its capabilities (e.g., "I am a 5A supported cable").

-

6. Adapters

Regarding legal adapters (like Type-C to A Male, Type-C to Micro-B), the spec adds a specific "Note":

"USB Type-C receptacle to USB legacy adapters are explicitly not defined or allowed."

(Clearly undefined or disallowed)

-

Pitfall Guide:

As engineers, we often receive strange custom requests from clients, such as "make an adapter from Type-C female to USB-A male". According to spec 1.2, this is non-compliant. This is because it could allow users to assemble illegal cable combinations (e.g., A-to-A), potentially burning out devices. During the project review phase, we must reject such designs based on specifications; this is the professional ethics of a wire harness engineer.

The USB Type-C 1.2 specification has brought the wire harness industry into an era of "mechatronics". For us engineers, "continuity, wire sequence, withstand voltage" are just the basics. "High-frequency impedance, CC logic, E-Marker programming, thermal control" are the keys that determine product viability.

Need a professional Type-C Wire Harness Customization Solution?

Theory is complex, execution requires expertise. Kaweei , as a senior custom wire harness manufacturer, understands USB Type-C specs and E-Marker processes deeply. We provide high-quality solutions from design to mass production. Whether for 100W PD fast charging or high-speed data transfer, we strictly control impedance and temperature rise to ensure your product lands compliantly.

Refuse inferior cables, choose professional quality. Contact Kaweei Now to get your exclusive engineering advice and quote!