Automobile wiring harness design process and method

The basic idea of automotive wiring harness design is to determine the circuit loop and calculate the voltage and current of each loop, especially the high-power equipment, according to the needs of the electrical equipment, select the matching connector according to the electrical equipment, determine the wiring harness cross-sectional area according to the current, and then design the wiring harness direction.

Wire harness design overview

1 The basic process of wiring harness development and design is as follows:

(1) According to the function table required by the OEM, all functional parts connected to the wiring harness are listed, and the component functions are confirmed with the corresponding electrical engineer, the ICD information is obtained, and the electrical principle layout diagram is determined.

The principles of each ECU system are checked, and each functional component is integrated into a complete wiring harness schematic diagram. Generally, the power supply system and the grounding part can be combined together using riveting points.

At the same time, the current size of each functional system is checked (including overcurrent or stall current, etc.) to ensure that it can meet the working requirements of electrical systems such as motors, switches, fuses, and blowers.

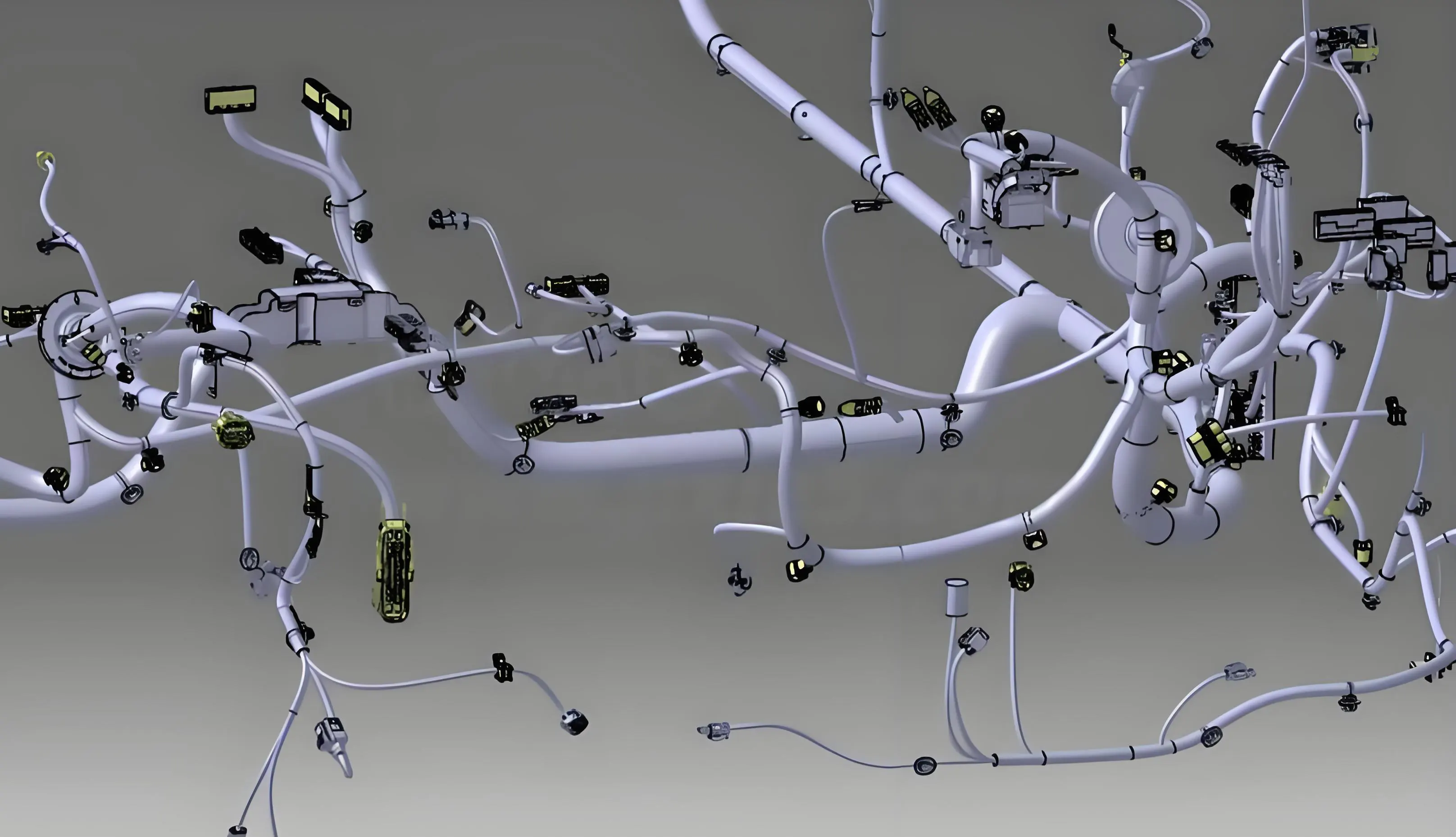

(2) Design the initial 3D distribution diagram, and use CATIA or UG software to complete the wiring harness direction distribution according to the processing and assembly sequence of the general wiring harness process. In this process, the installation position of the fuse box should be basically defined. The initial 3D distribution drawing generally reserves a certain margin.

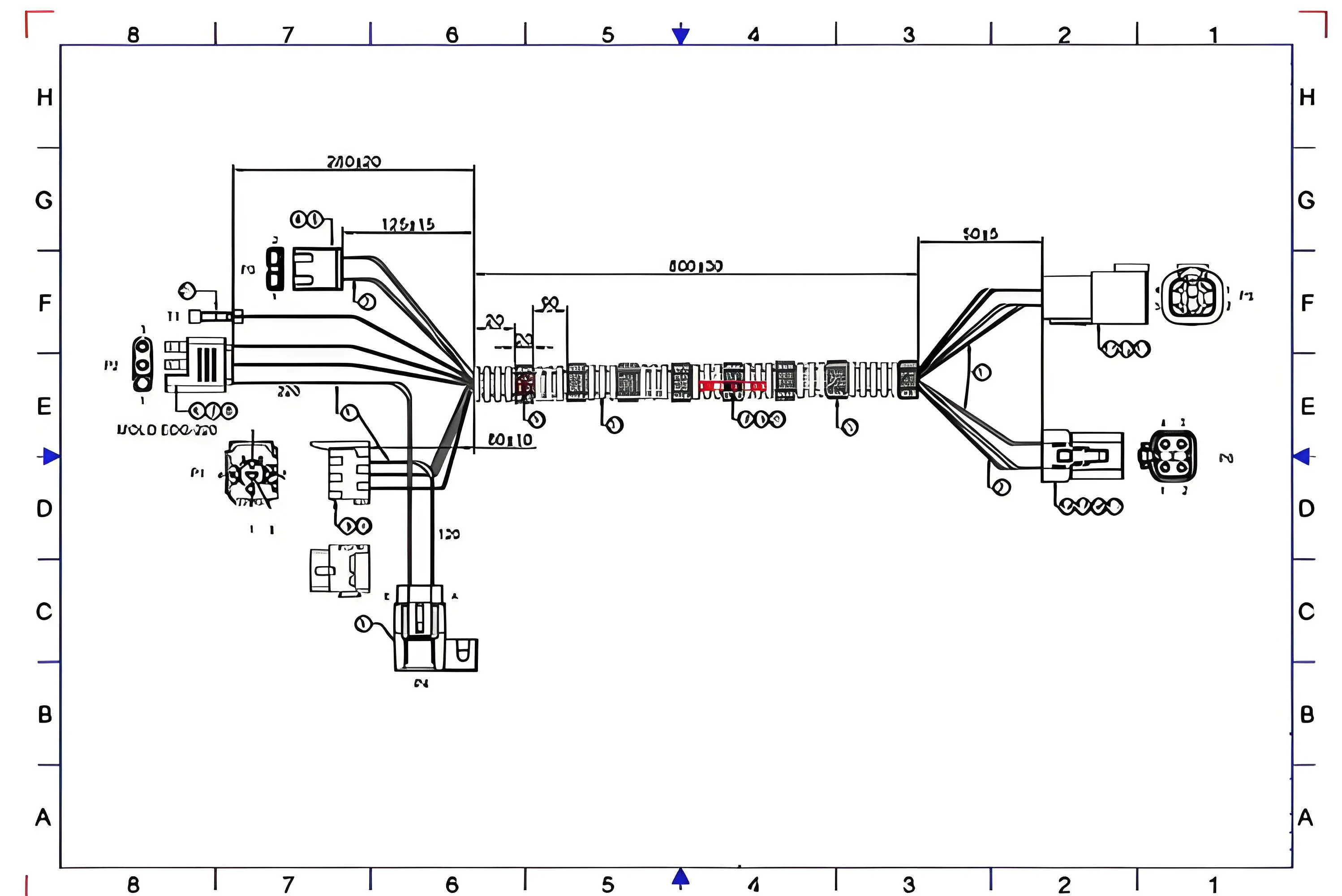

(3) Convert the 2D drawings. The 2D drawings refer to the industry standards, such as the relevant requirements in the QC29106 standard.

(4) According to the initial 2D drawings, make manual wiring harness samples and test install them in the car.

(5) According to the actual test installation results and trial operation results, the wiring harness 3D wiring engineer optimizes the direction or length of the wires, taking into account the dynamic situation.

(6) The wiring harness is used to connect the electrical functional parts of the whole vehicle. Due to the installation requirements of various electrical systems or the whole vehicle, the wiring harness generally needs to be continuously adjusted and optimized in conjunction with each system. That is, the entire development process is also a process of continuous optimization and updating of the design.

Design method

1. Principle design of wiring harness

(1) Request the vehicle manufacturer for the vehicle electrical functions, current requirements and other special requirements. And confirm all information such as the installation location of the electrical components, the assembly method of the electrical components and wiring harnesses, and the working environment.

(2) Refer to the functions and methods that the customer needs to achieve, and make electrical schematics and circuit layout diagrams.

(3) Energy distribution for each electrical component system, including the distribution of power lines and ground lines.

(4) Determine the wire diameter. First, obtain the current that the wire needs to pass through from the actual power of the electrical component;

Long-term working components use wires with 60% of the actual current carrying capacity (such as heating systems, entertainment systems, and security systems);

Short-term working components use wires with a current carrying capacity between 60% and 100%.

(For example, seat adjustment motors, window lift motors, angle adjusters, etc.).

2. 3D wiring design The three-dimensional direction of the wiring harness is generally based on the premise of meeting the installation of the vehicle electrical system, combined with the layout direction of the body sheet metal and the design of openings and slots, to make an overall layout.

In particular, the segmentation design and trunk positioning of the wiring harness should take the overall layout into consideration.

2.1 Requirements for 3D wiring of automotive wiring harnesses 3D wiring of automotive wiring harnesses is a complex project from start to finish. The following points are mainly used as references:

(1) Ensure that all electrical functional areas are easy to assemble, and the assembly section is as simple as possible to facilitate installation.

If there are parts that are not suitable for direct installation, you can consider built-in counterparts, install them separately and then assemble them together (this will increase the cost).

Door panels, interior decoration and other tail wires can be assembled separately. Try to ensure that traditional process and tooling can achieve the assembly process.

(2) In addition to assembly, we must also pay attention to maintenance and repair, which also needs to be easy to disassemble, that is, DFD (design for disassembly). When repairing, only a section of the wire is removed, which is much easier to operate than removing the entire wiring harness. At the same time, it saves costs and reduces risks. 2.2 Other details of wiring harness layout In addition to the above-mentioned convenience of assembly and disassembly, the following details need to be considered for wiring harness layout:

(1) Reserve sufficient margin (even at the lower limit of tolerance), especially for wiring harnesses between two or more parts with relative movement, the length required for the extreme position must be considered.

(2) The wiring harness cannot be kept in a taut state all the time, otherwise it will continuously form internal stress on the copper wire and accelerate its aging process.

(3) The wiring harness generally needs to be fixed with buckles or slots at intervals, and cannot be too long in a free state.

Parts selection

1. Wire selection When selecting wires, the focus should be on the functions and environment that the wires need to achieve.

For example, the engine wiring harness has a high temperature in the cabin and many corrosive substances, so it is necessary to select high-temperature, oil-resistant materials, such as Teflon or cross-linked PE.

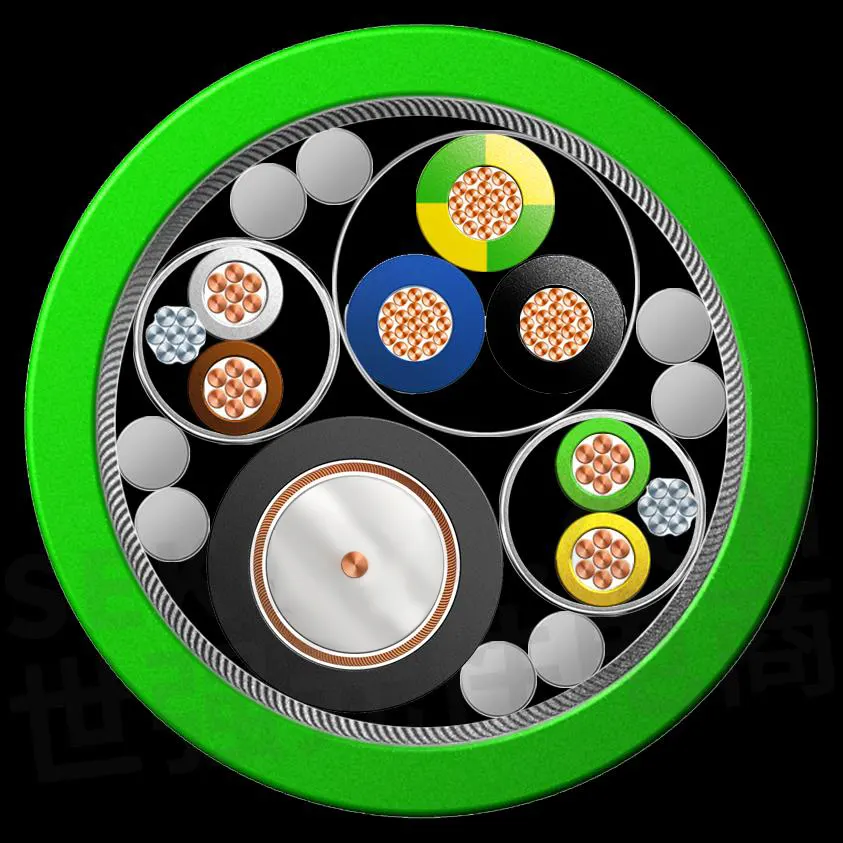

The trunk or door moves frequently, so it is necessary to select a wiring harness with relatively high elasticity, such as TPE or rubber. For some weak signal types, composite shielded wires are generally used, such as knock sensor wiring harnesses. The requirements in the cab are relatively low, and PVC wiring harnesses can be considered to save costs and be beneficial to lightweight.

2. Connectors The connector is the most important component of the wiring harness, which directly determines whether the wiring harness can achieve the most core connection function and plays a decisive role in the stability of the electrical system.

2.1 The selection requirements of the connector are first of all the coordination with the electrical components, the mechanical insertion retention force meets the use requirements, and the design with secondary lock is preferred. The contact resistance is as low as possible.

The insulation resistance and overcurrent meet the working current requirements of the wire. For wiring harnesses in wet areas, it is necessary to select waterproof sheaths and match them with appropriate sealing rings or blind plugs to meet the requirements of different waterproof levels in different areas.

2.2 Performance of raw materials of connectors

Sheath material (plastic parts):

Currently, the commonly used materials for connectors are mainly PA66, PBT, ABS, etc. Generally, some additives need to be added to increase the performance of the material, such as adding glass fiber to increase strength, adding plasticizers to increase softness.

Terminal material (copper parts):

The commonly used materials for terminals are brass, bronze and copper alloys. Brass has strong wear resistance, bronze has good castability, wear resistance and stable chemical properties, and copper alloys have excellent electrical conductivity, thermal conductivity, ductility and corrosion resistance.

In addition, considering salt spray and aging, terminals generally need to add different plating, tin plating, gold plating, etc. 2.3 Classification of connectors According to the matching form of connectors, they can be divided into: line-to-line and line-to-board.

Wire-to-wire connections include wire-to-cable or cable-to-cable connections, and are defined by the permanent connection of two individual wires or corresponding wires in two cables.

Wire-to-board connections are primarily a type of connection where one end of the connector is connected to the wire or cable, and the other end of the connector has fixed terminals that are welded to the substrate.

Wire harness wrapping design

Automobile wiring harnesses are affected by various external factors for a long time in the car, such as oil, dust, friction, water-like rust, etc. If there is no protective material on the wiring harness, the wires are easily damaged when exposed, such as broken wires and short circuits, which may cause functional failure.

Several commonly used materials for wrapping are as follows:

1. Corrugated tubes are the most important wire harness protection materials used in automotive wiring harnesses, generally divided into single-sided openings and sealed sleeves.

The materials used are PE, PA6/66, PP, etc., and the temperature resistance is generally -40℃~85℃, -40℃~125℃ and -40℃~150℃.

It has good wear resistance, and has good high temperature resistance, flame retardancy and heat resistance in high temperature areas.

PA material is better in flame retardancy and wear resistance, and PP material has advantages in bending fatigue resistance.

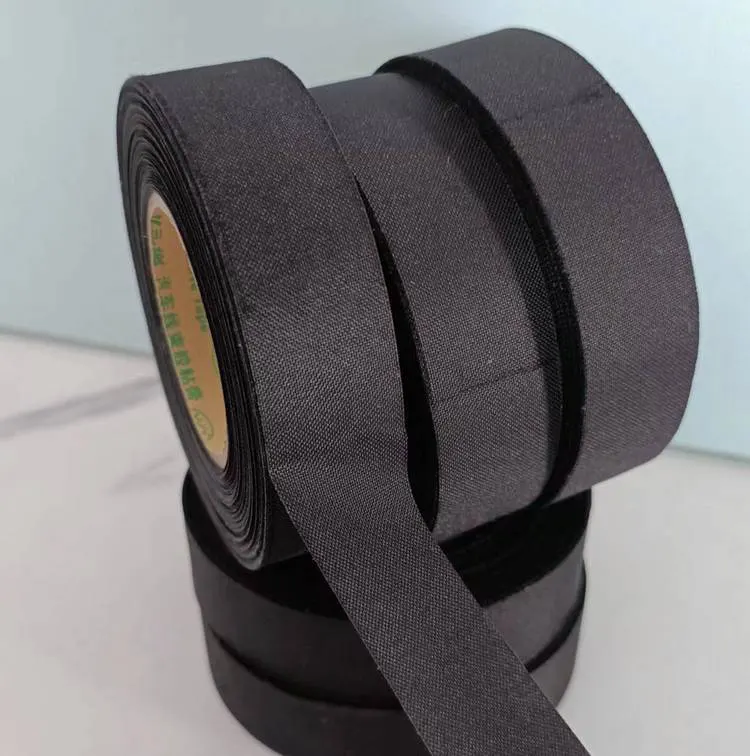

2. Tape Tape is the most widely used coating method in wire harnesses, and is mainly divided into three categories: PVC tape, flannel tape and cloth-based tape.

PVC tape has good insulation performance, and its temperature resistance is generally 80℃. After improvement, it is generally only 105℃. The noise reduction is not good, and the wire harness is hard after coating. At present, the VOC effect is generally poor.

The base materials of flannel tape and cloth-based tape are generally PET. Flannel tape has a temperature resistance of about 105℃, good noise reduction, and the wire harness is relatively soft after coating. Cloth-based tape has the best wear resistance, generally reaching the wear resistance level of D or E, and the temperature resistance can also reach 150℃, but the price is high, and it is generally used in vias or places with relative movement.

3. Braided mesh tube The material of the braided mesh tube is generally woven from PA66 monofilament or PET monofilament. Generally, there are open and closed types. The characteristics are very high wear resistance, but the noise reduction and cost are also high. It is generally used in areas that are subject to long-term relative motion.

The automotive wiring harness is called the vascular system of the car. With the rapid development of automobiles and the continuous improvement of user experience, the requirements for automotive wiring harnesses are also constantly increasing. Automotive wiring harness people are required to continuously research and develop new solutions to cope with the ever-changing needs.