Quality control standards for wire harnesses

The importance of Quality control in the wiring harness industry is reflected in the fact that it ensures the safety, reliability and consistency of wiring harness products, meets the stringent standards of the automotive, electronics and other industries, effectively prevents potential failures, enhances customer satisfaction, and earns the company market credibility and competitive advantage.

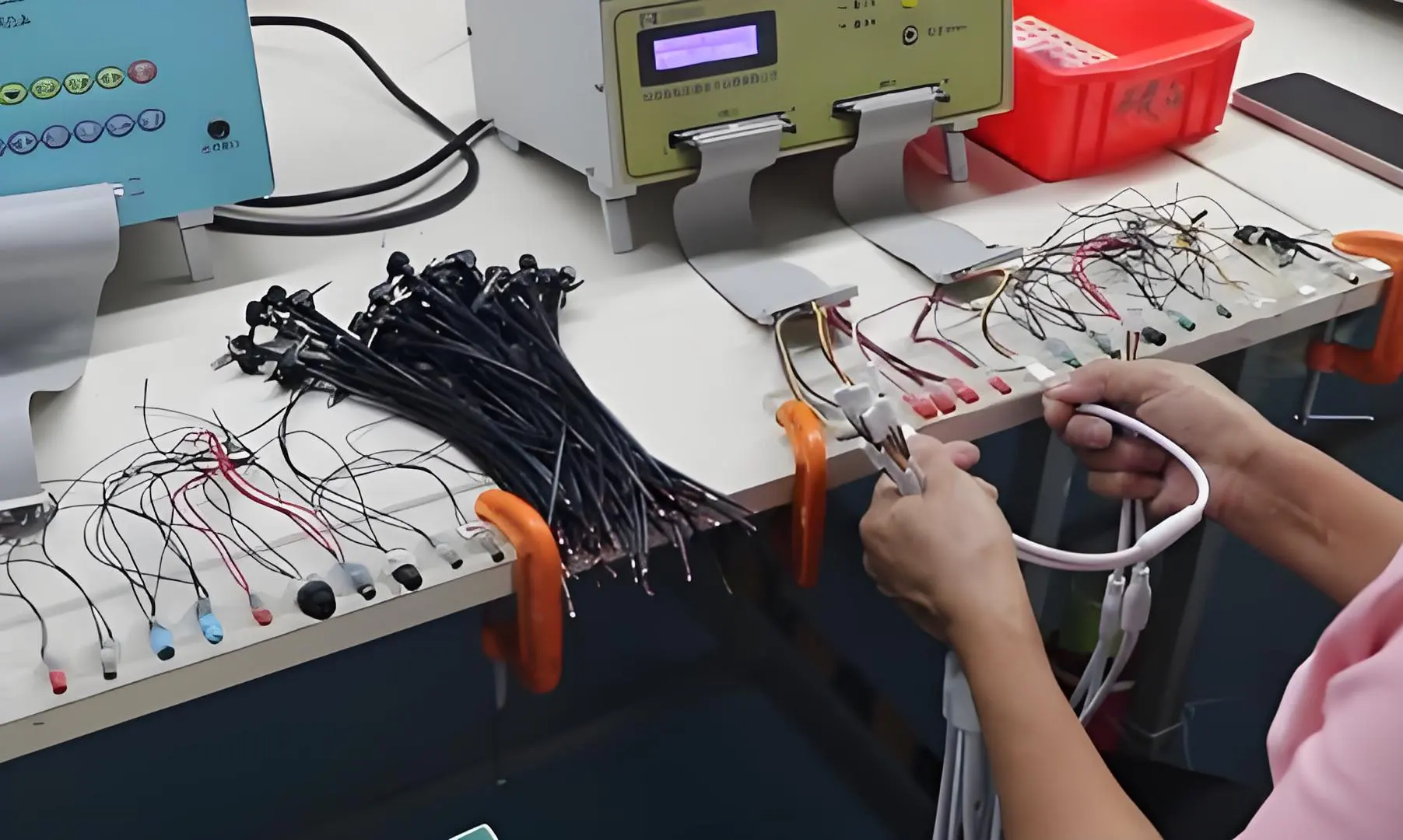

Quality Control Process

Wire harness quality control is a core process for ensuring product quality and system integrity. Strict adherence to standardized operating procedures is essential.

Visual Inspection

Objective: To assess the physical integrity of the wiring harness.

Scope: Inspect the outer coverings (e.g., conduit, tape, corrugated loom) for any damage, such as cuts, abrasions, deformation, or contamination. Check terminal housings for cracks, breakage, or missing components. Ensure no conductors are exposed and that crimping areas are free from damage.

Dimensional Inspection

Objective: To verify that the physical dimensions of the harness comply with engineering drawings and design specifications.

Scope: Measure critical dimensions, including overall length, branch lengths, breakout points of main lines to branches, and spacing between terminals. Ensure all dimensional tolerances are within specified limits to prevent issues like excessive stress or insufficient installation space during final assembly.

Wire and Terminal Inspection

Objective: To confirm the correct material specifications and reliable crimping quality.

Scope: Verify that the wire gauge, color, and temperature rating match the Bill of Materials (BOM). Check that the terminal model and plating are correct. Focus on crimp quality by assessing crimp height, width, and tensile strength (pull-test force). Ensure there are no defects such as high/low crimps, insufficient or excessive insulation support, or conductor strand damage.

Assembly and Securement Inspection

Objective: To ensure the harness assembly is structurally sound and correctly positioned.

Scope: Verify that all components, such as connectors, grommets, protective sleeves, and clips, are correctly installed and secure. Check that ties, clamps, and other mounting devices are properly positioned and tightened to the specified torque, ensuring the harness will not loosen or detach during operation.

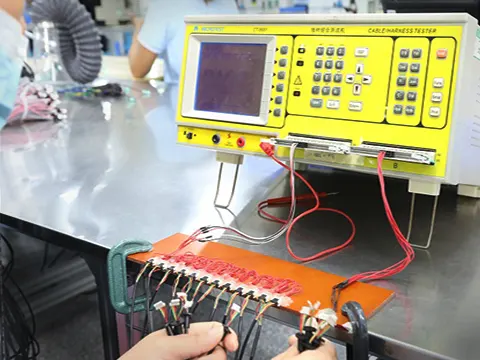

Electrical Performance Testing

This is a critical step to validate the harness’s functional reliability and safety.

Continuity Test (Open/Short Circuit Test)

Objective: To verify the correct electrical pathways and detect any wiring errors.

Method: Use a Cable Harness Tester (or Automated Test Equipment - ATE) to check for continuity in all circuits according to the schematic. The test must identify any open circuits (incomplete connections) or short circuits (unintended connections between circuits).

Insulation Resistance Test

Objective: To assess the quality of the insulation and prevent leakage currents.

Method: Apply a specified DC voltage (e.g., 500V DC) between all conductors and between conductors and the shield/chassis. Measure the insulation resistance to ensure it meets the minimum specified value (e.g., >100 MΩ). A low value indicates compromised insulation, which could lead to leakage or failure.

Dielectric Withstand Test (High-Potential Test / Hipot Test)

Objective: To verify the insulation system’s ability to withstand high voltages without breakdown, ensuring operational safety.

Method: Apply a high AC or DC voltage (significantly higher than the working voltage) between all conductors and between conductors and the shield/chassis for a specified duration. The test is passed if no dielectric breakdown (excessive leakage current) occurs. This is a critical safety test to prevent electric shock hazards.

Inspection Tools and Equipment

Visual & Dimensional: Calipers, micrometers, tape measures, go/no-go gauges, magnifying lamps, borescopes.

Electrical: Cable Harness Testers (ATE), Multimeters, Insulation Resistance Testers (Meggers), Hipot Testers.

Crimp Validation: Crimp Height/Width Micrometers, Tensile Testers (Pull-testers), Crimp Quality Analyzers (for cross-section analysis).

Inspection Standards and Non-Conforming Product (NCP) Handling

Acceptance Criteria: All inspections must be conducted against clear, documented standards, including engineering drawings, BOMs, and industry specifications (e.g., IPC/WHMA-A-620). The criteria for acceptance and rejection must be unambiguous.

NCP Procedure:

- Identification: Any harness that fails to meet the inspection criteria must be immediately identified and segregated from conforming products with a clear “Non-Conforming” or “Rejected” label.

- Documentation: Record all non-conformances in detail on an inspection report or NCP form, including the defect type, location, and quantity.

- Disposition: Based on the severity of the defect, authorized personnel will determine the disposition: Rework, Repair, or Scrap.

- Root Cause Analysis & Corrective Action: A root cause analysis must be performed for significant or recurring defects, and effective Corrective and Preventive Actions (CAPA) must be implemented to prevent recurrence.

Personnel Requirements and Safety Precautions

Personnel Qualification: Inspectors must be professionally trained, competent in reading harness drawings, familiar with inspection standards and procedures, and proficient in operating test equipment. They must be certified as qualified before performing inspections.

Safety Precautions:

- During high-voltage tests (e.g., Hipot), ensure the test area is clean and dry. Wear insulated gloves and post warning signs to prevent electric shock.

- Handle precision instruments with care, following operating procedures to avoid damage.

- Maintain a clean and organized workstation with proper tool and material storage to prevent accidents.

Record Keeping and Traceability: All inspection processes and results must be completely and accurately documented in inspection reports to ensure product traceability, facilitate data analysis, and support continuous improvement.

In summary, wiring harness Quality control is a systematic quality control process. Through standardized procedures, professional tools, scientific methods, and rigorous standards, it ensures every harness meets design and safety requirements.