Automation equipment electronic wiring harness solutions

As intelligent devices and automation systems continue to evolve rapidly,

custom electronic wire harnesses—often referred to as the "neural network" of electrical systems—play a crucial role in determining the reliability and stability of the equipment.

Kaweei presents a custom wire harness featuring Amphenol AT series connectors and LAPP premium cables.

This article provides an in-depth analysis of the material properties, manufacturing techniques,

and process details to offer a comprehensive reference for professionals and companies in the electronic engineering field.

I. Key Materials: The Perfect Integration of Performance and Compatibility

1. Amphenol AT06-6S-SR01BLK Connector Housing

Designed for harsh environments, the AT06-6S-SR01BLK housing is made of high-performance thermoplastic,

offering exceptional mechanical strength and chemical resistance. It operates reliably under high temperatures,

humidity, and corrosive gases. Its 6-pin design accommodates multi-line connections,

while a built-in strain relief structure mitigates stress from bending and vibrations,

effectively extending the wire harness lifespan. With an IP67 rating,

it is fully dustproof and waterproof—capable of operating even when briefly submerged in 1 meter of water—making it ideal for use in industrial automation and new energy systems.

2. AT62-16-0122 Nickel-Plated Terminal

Constructed from high-purity copper alloy, the AT62-16-0122 terminal offers excellent conductivity and mechanical strength,

supporting a rated current of 13A, suitable for most industrial applications.

Its nickel plating forms a dense protective layer that significantly enhances corrosion resistance. Even in saline,

acidic, or alkaline environments, the terminal maintains low contact resistance,

ensuring long-term electrical stability and reliability.

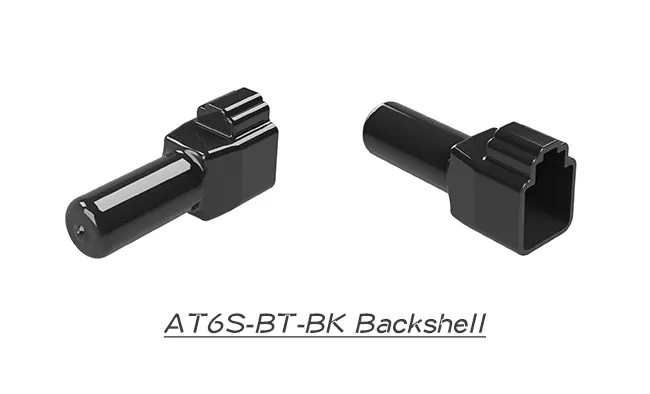

3. AT6S-BT-BK Backshell

Perfectly matched with the AT06-6S-SR01BLK housing,

the AT6S-BT-BK backshell is made from high-strength engineering plastic with added flexibility and wear resistance.

It also features UV resistance, making it suitable for prolonged outdoor use.

Its operating temperature range of -29°C to +100°C enables it to withstand extreme conditions.

When assembled, the backshell and housing provide dual-layer protection, effectively blocking dust,

moisture, and foreign particles to safeguard internal electrical connections.

4. LAPP 2216070 16AWG 7-Core Stranded Wire

As the core conductor, the LAPP 2216070 cable uses seven strands of high-purity copper,

delivering excellent flexibility and resistance to repeated bending—ideal for complex routing in dynamic environments.

The outer PVC insulation sheath offers robust dielectric performance with a rated voltage of 600V, ensuring safe current isolation and minimizing leakage risk.

In addition, the PVC material resists abrasion and oil contamination, making it suitable for harsh industrial environments.

The cable’s enhanced electromagnetic shielding also minimizes signal interference, ensuring stable transmission of both power and data.

II. Manufacturing Process: Precision Engineering for High Quality

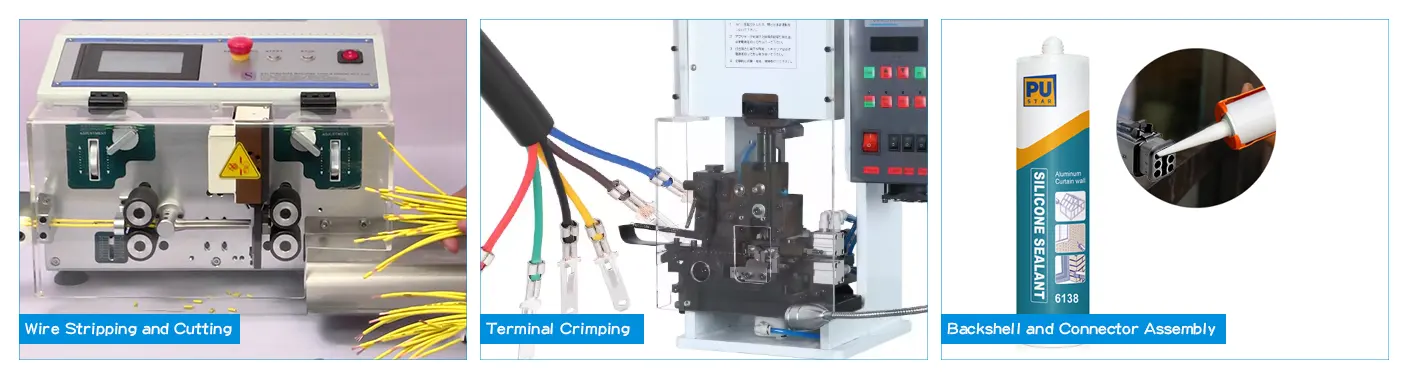

1. Wire Stripping and Cutting

The manufacturing process begins with automated precision wire-cutting machines that cut LAPP cables to exact lengths with a tolerance of ±0.5mm.

Next, specialized stripping equipment removes the PVC insulation at the cable ends with micron-level accuracy,

ensuring uniform conductor exposure without damage.

An intelligent monitoring system checks stripping depth and length in real time to prevent poor contact or short-circuit risks due to improper stripping.

2. Terminal Crimping

The AT62-16-0122 terminals are then crimped onto the stripped wires using a CNC-controlled crimping machine that applies precise pressure.

This ensures tight bonding between the terminal and conductor for a reliable electrical connection.

The crimping follows Amphenol's strict technical standards, ensuring a tensile strength ≥132N and contact resistance ≤5mΩ.

Each crimp is visually inspected and dimensionally measured by automated systems to eliminate defective assemblies.

3. Backshell and Connector Assembly

The crimped wires are threaded through the AT6S-BT-BK backshell,

aligned precisely with the outlet holes.

Then, the wires are inserted into the AT06-6S-SR01BLK connector housing in a predefined sequence using a positioning jig to ensure consistent insertion depth.

High-temperature waterproof sealant is applied at the connector interface to ensure IP67-level protection.

Finally, the backshell is secured to the housing using a snap-fit mechanism,

forming a fully protected wire harness structure.

III. Quality Control: 100% Rigorous Testing

1. 100% Continuity & Electrical Testing

Every finished wire harness undergoes 100% automated electrical testing covering voltage, insulation resistance, and continuity resistance.

All test results—including timestamp, parameters, and operator data—are recorded in real time for traceability.

Key testing parameters include:

- Voltage Test: 300V applied for 10 seconds to check for leakage or dielectric breakdown.

- Insulation Resistance: ≥5MΩ between conductors and insulation layers to ensure electrical isolation.

- Continuity Resistance: ≤3Ω between terminals and wires to ensure efficient power delivery.

2. Labeling and Final Inspection

Wire harnesses that pass testing receive a custom adhesive label with key product information,

including model, specifications, production date, and batch number, enabling traceability and inventory control.

A final inspection is conducted by quality control personnel to verify product appearance and perform sample functional testing.

Only defect-free products are approved for packaging and shipment.

Kaweei’s custom electronic wire harness, built with Amphenol components and LAPP cables, showcases superior environmental resilience,

electrical stability, and manufacturing precision. Its performance stems from meticulously selected materials, advanced production processes,

and comprehensive quality control. With these strengths, Kaweei offers highly reliable interconnect solutions for industrial automation,

new energy, and smart communication applications, setting a benchmark for professionalism and technical capability in the wire harness industry.