Wire Cutting Process and Quality Control

Wire cutting is a fundamental step in the wire harness manufacturing process. It ensures accurate assembly dimensions, neat appearance, and stable electrical performance.

The precision of this process directly affects the quality of terminal crimping, harness assembly, and bundling. To maintain production consistency and traceability, operators must strictly follow the process documents and work instructions to ensure that the length, tolerance, and quality of each wire meet engineering specifications.

Wire cutting operation process

1. Material Receiving and Label Verification

Receive the wire according to the production order. Verify the material label, type, color, specification, and batch number to ensure they match the engineering drawing and BOM.

If any discrepancy is found, report it immediately. Substitutions are not allowed without authorization.

2. Equipment Preparation and Setup

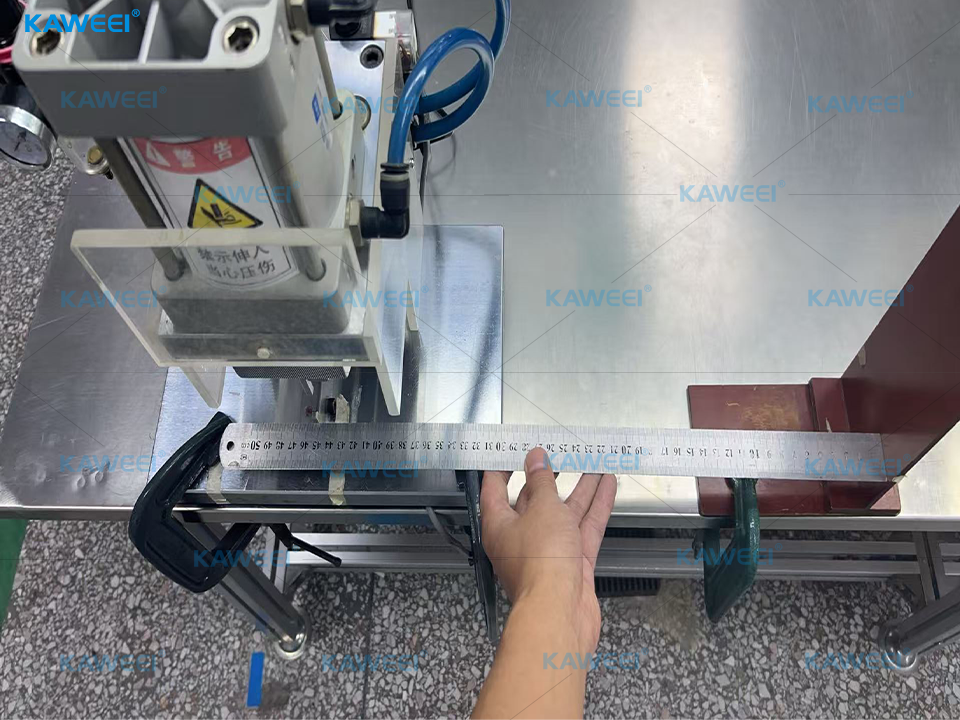

Secure the pneumatic wire-cutting machine to the workbench. Check the air pressure, cutting blade, and control system to confirm normal operation.

Ensure the blade is sharp and the machine is firmly installed to avoid dimensional deviation caused by equipment instability.

3. Determining Cutting Length per Engineering Drawing

Refer to the engineering drawing and process requirements to measure the specified wire length using a steel ruler or measuring device.

Adjust the machine positioning stop to ensure accurate length settings.

4. Cutting Operation

Straighten the wire, position one end, and align the other with the blade.

After confirming correct positioning, step on the foot pedal to perform the cut. Maintain a stable motion during operation to prevent wire displacement or uneven cutting.

5. First Article Verification

After the first piece is cut, a first-article inspection must be performed by a quality inspector or team leader.

Inspect dimensions, appearance, and cut surface flatness. Only after passing inspection may mass production begin.

If the first article is non-conforming, adjust the equipment and re-verify before continuing.

6. Placement After Cutting

Arrange the cut wires neatly in the designated workstation or container.

Avoid bending, tangling, or contamination.

Maintain uniform sequence and direction to facilitate subsequent processes such as crimping, stripping, or assembly.

Operational Precautions

1. Cutting Surface Requirements

The cut surface must be flat and smooth, with no burrs, drawn wires, or skewed cuts.

Length deviation must be controlled within the specified process tolerance.

2. Safety Regulations

Do not place hands near the blade area during operation.

Unauthorized personnel must not touch the equipment.

Before starting work, ensure that all safety guards and protective devices are functional.

3. Wire Protection Requirements

Do not drag wires on the floor to prevent contamination or insulation damage.

Avoid kinking, bending, or compressing wires during operation.

4. Appearance and Quality Requirements

Wire surfaces must be free of stains, scratches, dents, or other defects.

The cut length, color, and model must match the production order.

5. Material Segregation Management

Good and defective materials must be clearly separated and identified:

- Good materials are marked with blue labels and stored in blue bins.

- Defective materials are marked with red labels and stored in red bins.Both types must be physically separated to prevent mixing or misuse.

Cutting Process Inspection Items

To ensure the stability of wire-cutting quality, inspectors should perform regular sampling inspections. Main inspection items include:

1. Material Specification Verification

- Confirm that wire type, color, and cross-sectional area are consistent with the engineering drawing.

- Verify that the material batch matches the production order.

2. Cutting Dimension Verification

- Use calibrated measuring tools to randomly inspect wire lengths.

- Check cut surface flatness and verify that dimensional deviations are within the allowed tolerance.

- If abnormalities are found, notify process or equipment personnel immediately for adjustment and re-inspection.

Wire cutting is a critical precision process in wire harness manufacturing.

Through standardized operations, proper material management, and consistent inspection, Kaweei ensures stable dimensions, clean appearance, and reliable production consistency.

Every cut wire forms the foundation for precise crimping and high-quality harness assembly.

Kaweei specializes in custom wire harness solutions for a wide range of applications.

If you have wire harness requirements, please contact Kaweei anytime — we’re ready to provide professional, reliable, and efficient service.

Faq

1. What is wire cutting in wire harness manufacturing?

Wire cutting is the process of cutting wires to precise lengths according to engineering drawings. It ensures accurate assembly dimensions, neat appearance, and stable electrical performance in wire harness production.

2. Why is precision important in wire cutting?

High precision in wire cutting directly affects the quality of terminal crimping, assembly accuracy, and overall harness performance. Even small deviations can lead to electrical or dimensional defects.

3. What inspections are performed during the wire cutting process?

Inspections include verifying wire type, color, and length; checking cut surface flatness; and ensuring tolerances meet specifications. Regular sampling helps maintain stable cutting quality.

4. How does Kaweei ensure wire cutting quality and consistency?

Kaweei follows strict process documents, uses calibrated equipment, and performs first-article and routine inspections to ensure each wire meets engineering and quality standards.

5. What industries can benefit from Kaweei’s wire harness solutions?

Kaweei provides custom wire harness solutions for diverse applications, including automotive, industrial equipment, consumer electronics, and more — delivering professional, reliable, and efficient service.