what is wiring harness?

Automotive wiring harnesses are assemblies of wires and cables that connect all electrical and electronic components in a vehicle, such as sensors, electronic control units (ECUs), batteries, and actuators.

They function as the vehicle’s “neural network,” responsible for transmitting power and data to support both critical operations such as steering and braking, as well as secondary features like ventilation and infotainment systems.

Given the harsh operating environment of vehicles—including high temperatures, humidity, vibration, and dust—wiring harnesses must not only ensure the stable operation of electrical systems but also provide robust protection against abrasion, moisture, short circuits, and even fire.

By bundling several kilometers of wiring in an organized manner, harnesses also save space, simplify installation, and enable standardized production, thereby greatly improving assembly efficiency.

How is a wiring harness created?

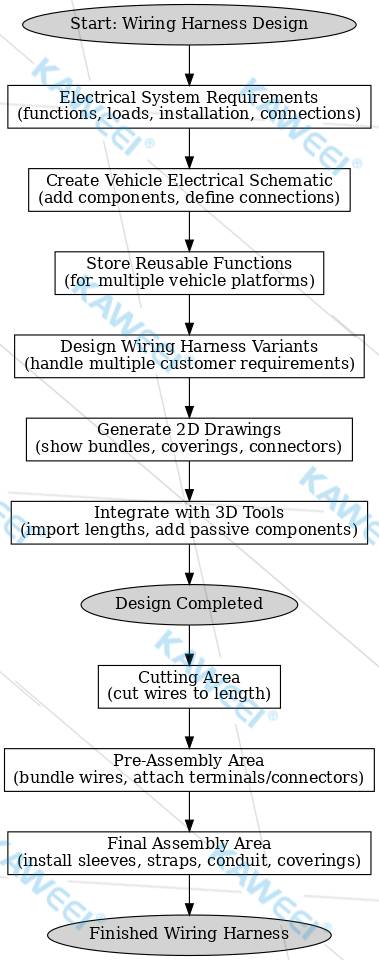

The creation of a wiring harness is divided into two stages: software design and physical manufacturing.

In the software design stage, electrical system engineers first define the overall system functions, loads, and connectivity requirements.

Based on these requirements, the complete vehicle electrical schematic is drawn, and a reusable component library is established.

Next, designers handle different customer configuration demands in a modular manner, avoiding the need to design separately for each variant, thus saving both time and cost.

Upon completion, 2D drawings are generated, showing wire bundling methods, protective materials, and connector layouts.

This design data is further integrated with 3D mechanical design tools to accurately determine wire lengths, add clips and other passive components, and ultimately form a complete design package.

During physical manufacturing, the design data is transferred to the factory, where it goes through cutting, pre-assembly, and final assembly stages, resulting in a finished harness.

What are the challenges in creating a wiring harness?

However, the wiring harness design process is far from straightforward.

As the level of vehicle electrification increases, the complexity and challenges of harness design continue to grow.

The first issue is data inconsistency and difficulties in reuse. Global teams often use different tools for design, which easily leads to divergence in “shared” data over time. This makes reuse difficult and negatively impacts project schedules and costs.

The second issue is low system integration. Design changes cannot be automatically synchronized across multiple tools and databases, often requiring semi-manual operations that increase the risk of errors.

Finally, traditional processes rely heavily on physical prototypes to identify issues, meaning that errors are often discovered in the late stages of a project. This severely delays time-to-market and consumes significant resources.

To address these challenges, modern Electronic Design Automation (EDA) tools provide effective solutions.

First, EDA tools ensure data consistency and reusability across the entire workflow through platform-driven design and top-down, connectivity-based design processes, thus reducing time-to-market.

Second, by establishing a unified central design database, they enable concurrent multi-user design and option management, avoiding the quality issues caused by poor system integration.

Most importantly, EDA tools bring simulation and verification forward into the design stage, achieving true “shift-left” design.

Designers can use built-in simulators to perform DC analysis, voltage drop analysis, and connectivity checks early in the process, identifying and resolving problems before physical prototyping.

This not only improves design quality and system robustness but also enables extensive “what-if analysis” to optimize electrical system architecture and achieve load balancing.

Kaweei specializes in efficient, high-quality custom wiring harnesses. From automotive to industrial and electronic applications, we deliver reliable harness solutions tailored to customer needs. With advanced manufacturing and strict quality control, Kaweei ensures safer, more durable connections that make both development and mass production easier.

In conclusion, as a core component of the vehicle electrical system, the quality and efficiency of wiring harness design directly impact overall vehicle performance and development timelines.

Facing increasingly complex design requirements, modern EDA tools—with their strengths in data consistency, system integration, and early-stage design verification—provide powerful support for harness engineering and have become a key driver in the advancement of automotive electrification.